When we try to locate a packaging foil material for our products, of course, we need to locate enough quality at the loest cost. PET12/VMPET12/LLDPE should be considered as one of the most common used foil laminate that acheive the fine package for most products, with superior advantages. In this post, we are going to give a further analysis on this foil, so the customers can get a good understanding on this.

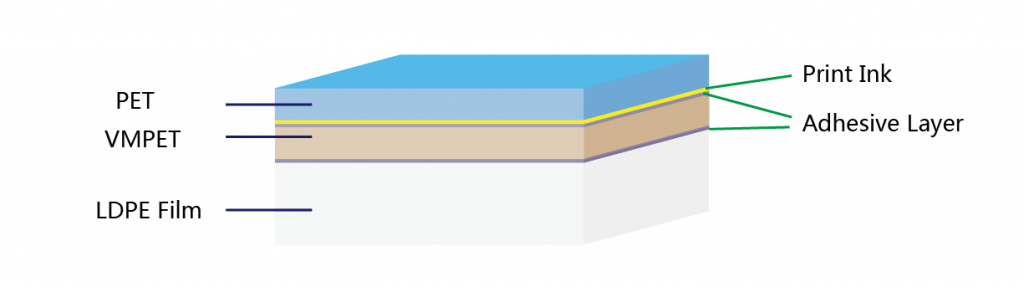

Foil Structure

PET12/VMPET12/LLDPE foil structure achieve the mult-functioin for the foil laminate with each layer function as below.

- PET12, means polyester film 12 microns, works as the outer print substrate layer. PET film is considered as one of the best substrate films to process print,coating and laminate craftsmanship.

- VMPET12, means metallized polyester film, 12 micron, that is considered as one of the best barrier film materials in the flexible packaging industry, works as middle bone layer and barrier layer.

- LLDPE film, short for linear low density polyethylene film, works as inner sealing layer.

Print Effect

This foil structure is able to present execellent print effect, as of below reasons

- Good clarity for PET film

- Good dyne level for PET film

- Sufficient leveling for inks

- Metallized PET film works as reflective background, that is able to create much more solid effect

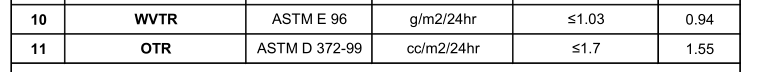

Barrier Performance

VMPET film is one of the most common used barrier film materials in flexible packaging industry, that is able to provide enough barrier performance for most products, like food, pet foods, dry nuts, chemical products, etc. Of course, the barrier property should be seriously considered when you are trying to locate the suitable package for your products, and below data of WVTR (water vapor transmission rate) and OTR (Oxygen transmission rate) for PET12/VMPET12/LLDPE85 is listed as below for your reference.

If you want to get more information of barrier performance for other barrier film, read here https://www.vp-packaging.com/substrate-property/barrier-property/wvtr-and-otr-for-most-common-high-barrier-film-material/

Roll Foils

This foil laminate can be easity processed into roll foils, and going to work on the customer’s forming and sealiing machine. With stable mechanical strength and high temperature resistance, this foil laminate is able to realize smoothe appearance when it is sealed into final packages.

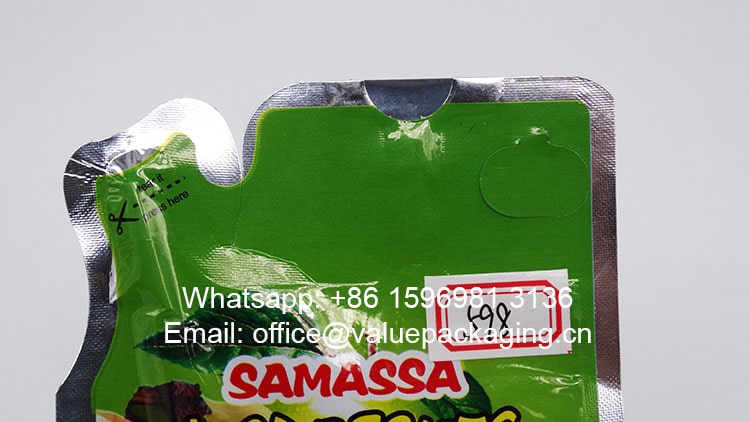

Standup Pouch

PET film is of good rigitidy, the same for VMPET film, so with two layers of PET substrate film into this foil structure, it is achieved with fine rigidity and toughness that can meet the requirements for standup pouches. Of course, the thickness for final foil laminate matters, and upon our experience, the thickness should be at least 100 microns (PET12/VMPET12/LLDPE75) if you want to achieve a good standing effect.

Matte Lacquer Coating

Matte lacquer coating can be applied on the outside of PET film, that is intended to create quality surface and visual effect for final packages. You can watch the video below to check the matte finish quality on our PET12/VMPET12/LLDPE75 foil which is intended for pet treats products.

OK, here are the basics for PET12/VMPET12/LLDPE foil materials, and you are welcome to reach us if you have other questions. Glad to be of help.

we are looking for good quality at the lowest cost. PET12/VMPET12/LLDPE Coffee standup pouch film is of good rigidity and should have superior advantages to our stock Coffee pouches with and without a one-way gas release valve. The valve prolongs coffee shelf life and freshness. The bags we are looking for should available in every colour and the inside Silver making for an eye-catching point of sale product display. Either face is suitable for prominent brand labelling on the bag. Coffee standup pouch film is of good rigidity, the same for VMPET film, and so with two layers of PET substrate film into this foil structure, it is achieved with fine rigidity and toughness that can meet the requirements for standup pouches.I also Inquiring about a machine system to measure my foiling design packages as well, please ?

for the coffee package

Which better for katchup mayonnaise sachet 10g foil rolls thickness and how many one kilogram of the fiol rolls make psc of 10g bags.

Dear Suleman, for ketchup mayonnaise, we are producing premium quality foils with triplex layer PET12/AL7/LDPE60 for 10g package. Do you locate the size for your 10 gr bag? we will reach by email for further assistance.