Description

500ML-standing-doypack-package-for-cricket-mix-top-quality

1 Introduce

This top-quality standing doypack package for cricket mix is

crafted for a company specializing in food packaging solutions, which presents its

premier food-related products to the market. This package is well able to

showcase exceptional quality packaging for the meat items and serve as great

protection during storage, transport, and distribution.

Here let us further understand this God’s late packaging bag also hope to be able to provide some help for food packaging.

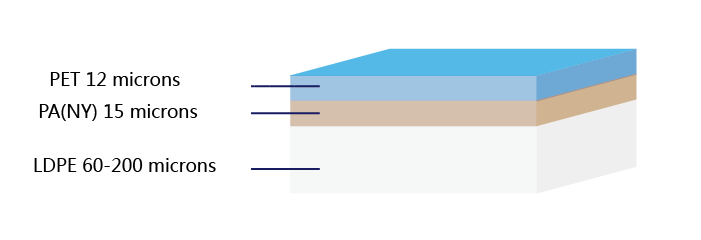

2 Foil Materials

This foil material is a reinforced structure with excellent properties for cricket mix doypack. The foil structure is NY15/NMET12/LDPE, with a graphic as below.

Next, let’s further understand the structure of this packaging material

NY15 it is very popular in the food packaging industry because it can keep food fresh and can display important information like whether the product is organic, vegetarian, or halal, and if it contains allergens. And the market demand is great in food and medicine packaging.

VMPET12 also called vacuum metallized polyester film, that is achieved under

vacuum conditions to depasit a thin layer of aluminum atoms onto the surface of

PET (polyester) film substrate and realize a brght metalic fim that A large number of flexible packaging and vertical bag packaging.

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. Its advantages are toughness, flexibility, corrosion resistance, and light and easy plastic chemical resistance and impact resistance. It can increase the tightness of food and store food better.

3 Properties and Quality Assurance

3.1 Exquisite print quality

standing-doypack-package-for-cricket-mix-top-quality

Our crafts are done on our rotary concave press, which can print up to 10 colors. Through superior technology and process to meet customer needs.

3.2 Dimensional Stability

500ML-standing-doypack-package-for-cricket-mix-top-quality

As production and packaging companies adopt high-speed filling lines to improve production efficiency on cricket mix.The dimensional stability of the doypack is becoming more and more demanding. We have a good understanding of this, and

And we are doing our work to narrow the dimensional tolerances for each order we supply in the long run.Generally, for 120g cricket mix doypack, the tolerance should be within 2%, which is mostly in the market.

3.3 Steady Standing

500ML-standing-doypack-package-for-cricket-mix-top-quality

The bottom of this cricket mix doypack let the goods better stand on the shelf.Make the product more stereoscopic

3.4 Smooth Inner Zipper

The inner zipperlock design allows the cricket mix bag to be easily opened and merged, creating a straight line effect and maintaining the original integrity of the package. At the same time, this design also serves as a moisture-proof function. You can see that the zipper is embedded in the doypack in a gorgeous way without any wrinkles.

3.5 High Barrier Performance

As explained previously, this foil laminate is finalized with a layer of thin aluminum metal sheet, which is of the best barrier performance against oxygen and moisture vapor. Usually, the roasted beans should be well protected to keep the original flavor and fragrance for a prolonged period, to enable the beans enjoyed by the end consumers.

3.6 Great Mechanical Strength

This reinforced laminated foil can greatly protect cat food ranging from 100g to 120g volume.

We perform various inspections and tests to check the mechanical strength of the finished pouch, like drop tests, hard sudden strikes, anti-pressure tests

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material PA15/VMPET12/LDPE in the Technical Date Sheet part of this post.

3.7 Easy Tearing Notch

The tear-off design allows consumers to open the package more easily. Because it is located above the inner zipperlock, it does not damage the functional structure of the bag.

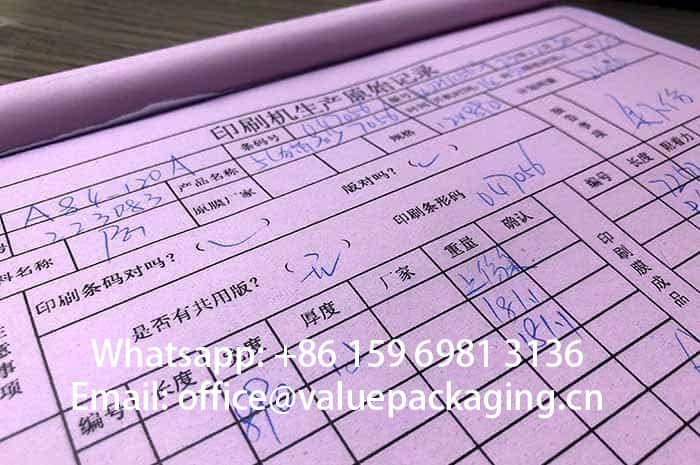

4.1 Manufacturing Traceback

Our manufacturing plant adopts strict quality control measures to ensure every order. Single can meet the requirements of specific customers. With more than ten years of experience in this field. We finalized this QC manual standard to ensure that every order is followed. Follow the correct procedure. Please allow us to guide you to learn more about our QC system.

4.2 Manufacturing Traceback

We use a strict recording system to record production details, such as environmental conditions, process parameters, production equipment, etc

Conditions, etc., which allow us to trace back when something goes wrong.

4.3 QC Test Report Against Each Order

QC test report will be issued for each production order, and the core products will be evaluated. Have to the customer’s high appreciation. You can read the QC test report for 250g and 1000g coffee bag orders here.

4.4 Print Inspection

At our manufacturing plant, print checks are always carried out in a serious way, as we always are. Will not allow a client’s artwork to be realized in a way that deteriorates their business. In our gravure printing. On the brush machine, there is an online inspection system that can eliminate more than 98% of insects in the printing process. You can see how it works on our control panel.

There is also supplementary off-line inspection equipment, to allow us to do the print inspection again whenever it seems necessary.

Perform an airtightness test on each order. The finished coffee bag should be completely sealed so that the product is protected from oxygen and moisture in the environment. We’ll use the equipment below.

4.5 Airtight Property Test

The finished coffee bag should be completely airtight, to get the products well-protected from oxygen and moisture in the environment. We perform the airtight property test against each order with the device as below.

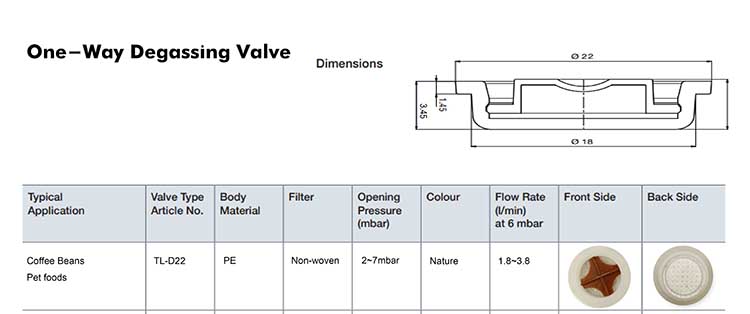

4.6 Gas Release Property Test

The gas will be released from the inside when the air pressure for the inside is 2~7 mbar than the outside environment. Usually, we will immerse the valve welded bag under the water, and check if the degassing valve works well.

4.7 Drop Test

Drop test should be considered as a very reliable way to check if the coffee bag strength is enough to meet the various conditions, as it copies the way when the products falls off the good shelves, and the finished bag will suffer great sudden shock. In our daily QC work, w. perform drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to drop the filled coffee bag from 1.6m high, for 5 times.

4.8 Hard Sudden Strikes on inflated coffee bags

Hard sudden strikes should be taken as a more fierce test method than drop test, as it causes much higher force on inflated packages.

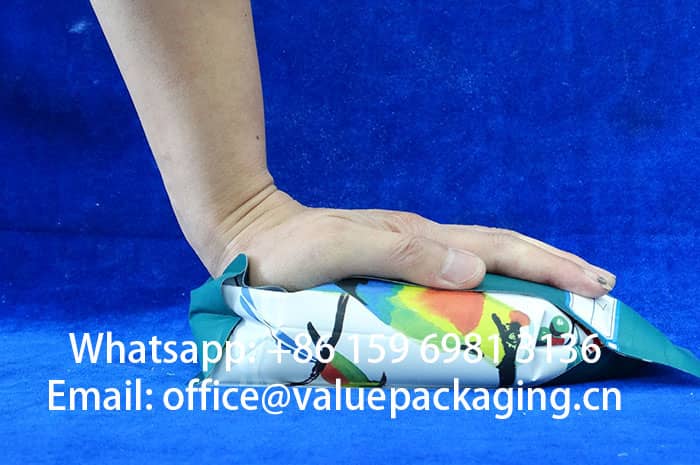

4.9 Anti-Pressure Test

Pressure testing is another effective way to determine whether the final packaging can make a big difference to the product

Protection, especially for liquid products such as household detergents and windshield washer fluids. For coffee bags, We will carry out the pressure test in the daily QC work to ensure that every order is a great machineGun strength complete.

Coffee bag leakage or damage, whether it is for the distributor or for the manufacturer, is definitely disaster. We never thought this would happen to our client’s business.

Sometimes, for easy and quick operation, we may have a person standing well sealed and inflated. On the coffee bag, check for any burst.

Reviews

There are no reviews yet.