In rotogravure printing of flexible packaging, print cylinders represent one of the largest upfront costs, especially for some businesses who may need to update their artwork regularly. For coffee brands and FMCG companies running multiple SKUs, seasonal designs, or private-label projects, it is a proven way to reduce cost when you know how to share print cylinders across multiple artworks.

However, it is not just a shortcut in artwork design. It requires insightful penetration into aim market, thorough understanding on your product, early business planning, technical understanding, and close coordination between brand, designer, and us packaging manufacturer.

In this article, we will explain what cylinder sharing is, when it works, when it doesn’t, and how to implement it correctly, in the hope of cost-savings for our customers.

1. What Does “Sharing Print Cylinders” Mean?

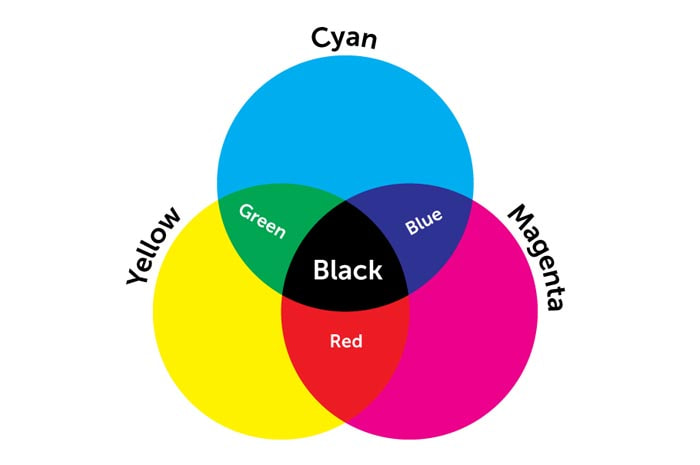

To understand sharing print cylinders, we have to understand the formation of colorful artwork printing in gravure printing. Generally speaking, the figures, elements, information, texts etc are presented to our human eyes in CMYK color overlapping.

In plant production, each color can only be achieved by the function of one print cylinder, as shown in the picture below, which showcases a typical physical form to achieve the finalization of one color onto the clear substrate film.

The information of each color will have to be engraved onto the metal cylinder, with tiny engraved cells on the surface, to hold and then transfer the printing inks to various substrates, as you can see some area on the print cylinder is engraved with the artwork information.

Always, an artwork will have to be formulated by serveal basic colors, not to mention matte varnish will also cost another print cylinder. So, in the production of gravure printing, the print press will have to be able to provide a set of print units, with our maximum capability up to 10 colors, to meet the various demand of artwork printing.

Through the picture below, you can see our teammate Charles standing by the print units numbered with ②, and other print units follow in the queue.

As some artworks may share the same elements, same background, so in the production of rotogravure printing, some cylinders are exactly the same to print these information. And there is no reason to re-make the same cylinders, then sharing the same print cylinders become a reality.

2. Why Cylinder Sharing Matters in Flexible Packaging

As an artwork may need a separate complete set of gravure cylinders to achieve the work, different artworks may require different sets of gravure cylinders. Gravure cylinders are precisly-engraved, durable and designed for long production runs, and expensive, with the common price USD 90 per cylinder during our quotes.

So, let’s do a calcultion.

Assume you have 4 artworks to print, and each artwork is composed in 7 colors, that means you will need 4*7 = 28 cylinders in total, and that would need you an initial investment of 28*90 = USD 2,520.

When we stand on the side of sharing print cylinders, for example, we just make one cylinder varied from each other, that means 6 printing cylinders can be shared in all 4 artworks, then there will be 6+4 = 10 cylinders needed, which means a large drop in the initial investment of USD 10 *90 = USD 900.

Furthermore, the print cylinders will have to be updated if you have change in your artworks. You may face the risk of spending more on print cylinders when all of you artworks are quite different from each other.

You can also be able to speed up the launch of new SKUs when you builds on the basis of sharing print cylinders.

3. Which Parts of an Artwork Are Best for Sharing?

To put it simply, we share a standup doypack mockup as below. Not only it adapts a minimalistic design which can minimize the quantity of print cylinders needed, but also it chooses a unified design system across these 3 SKUs which enables the maximum of print cylinders sharing.

We are going to give an elaborate explanation on this mockup, for your very best favor.

a. Minimum print cylinders needed for each Sku

There are only 3 gravure cylinders needed to print each SKU.

The logo, product name and relative information are set in black color on the upper part in front, which can be printed through black cylinder.

The information of each Sku is listed in the lower spot color background in white color. The text area is hollow-carved on the spot color cylinder, and then white background will present the texts in white color after gravure color overlapping.

The white background will be printed in full web, working as a solid reflective layer for the whole artwork.

So, this artwork can be finalized by Black + Spot Color + White, total 3 gravure cylinders.

a. Maximum sharing of print cylinders

The black cylinder carrying the logo and product name is fixed, and the white cylinder printing full white background is the same, so these two cylinders can be shared across all the Skus.

The only cylinder that needs to be changed when the customer launch a new SKU is the front lower spot color block. Different texts can be hollow-carved on the spot color cylinder, and different white texts will appear to address the information of different SKU.

In this way, for FMCG companies with frequent artwork updates or mutiple SKUs under, this strategy is especially valuable.

So, upon our experience, the most commonly shared parts in artworks are listed as below.

- Brand logo

- Brand logo

- Background colors or gradients

- Repeating patterns or textures

- Decorative frames

- Static legal icons (recycling, food safety symbols)

- Product name (sometimes)

The variable parts may be better to be carried by separate cylinders, with some common contents as below.

- Product name

- Flavor or roast level

- Origin

- Net weight

- Language versions

- Country-specific regulatory text

- Limited edition graphics

- Bar Code

The goal is to better finalize the sharing of print cylinders , so only 1–2 cylinders need replacement instead of 5–8.

4. Things Planned Ahead, Especially Artwork Design

To make the best use of cylinders sharing, you need to get things planned ahead, not to fix a problem when you come close to it. Especially the artwork design, that will influence every aspect of your package and branding. It may be too costly when you find you have to re-launch your artwork.

Below list may help you to finalize a good planning for your artwork.

- Designing a fixed background layer

- Reserving specific zones for variable content

- Aligning text blocks to a consistent position

- Avoiding overlapping between fixed and variable elements

One kindly and valuable reminding is, always update your needs with us packaging supplier, so we can do the best for your benefits, as not every designer is familiar with gravure printing, and they may drift into a wrong way with lots of investment in print cylinders.

5. Typical Cylinder Sharing Scenarios

Here are common, proven use cases:

Multiple Flavors, One Brand

Same background and brand identity

Only flavor name and color bar change

Private Label for Multiple Clients

Same structure and layout

Client logo changes only

Multilingual Versions

Identical artwork

Only text block changes

Seasonal or Limited Editions

Core design reused

Small graphic or label area updated

These approaches allow fast market response with controlled cost.

6. When Cylinder Sharing Is NOT Recommended

Cylinder sharing is not always suitable, with some occasions in the list below.

- Each SKU has a completely different design

- Brand positioning requires high visual differentiation

- Frequent color changes are expected

- Short runs dominate production volume

Addtionally, unappropriate cylinders sharing across mulitple skus may improve the risks of wrongly used cylinder in the order production in our manufacturer plant, when there is very subtle difference from different Skus.

This is not just a kindly warning, however we had several accidents of wrongly used cylinders in our history, which were caused by the very subtle difference across Skus, and our workers and QC personnel did not recognize it.

Luckily, we learned our lesson and we have developed a fine system to validate the sharing of print cylinders and now become an experienced manufacturer that is decided to the reliable and in-time supply of packaging materials to our customers.

7. Conclusion: Cylinder Sharing Is a Wise Business Strategy

Sharing print cylinders is not about compromising design. It is a wise busienss strategy to minimize the investment, especially in the startup period, and make the best use of technician to grow a business. We are surely be glad to support our customers with a cost-effective realization of their artworks, and allow them to grow their business at a minimum cost.