When it comes to coffee packaging, design and cost are often in quiet tension. Every roaster dreams of a bag that looks premium, protects freshness, and improve the sales of their products smoothly — yet fits within a sustainable budget.

The truth is, great packaging doesn’t have to be expensive. You can always find a better way to finalize your ideal packaging at a tuned cost when you know how to play smart.

Over the years, we’ve seen that the most successful coffee brands aren’t the ones who spend the most on packaging — but those who penetrate into the true demands of their customers in the market, and get their products well communicated with the customers and transited to their hands in a smart package.

In this post, we’ll explore how to make your coffee packaging designs more cost-effective, without compromising on the look, feel, or freshness your brand deserves.

1. Start with the Right Packaging Format

The first decision to make before you ever think of a coffee packaging design is the bag format, as every other thing, like cost comes after it.

There are mainly 4 packaging formats occupying the coffee packaging market, shows in the picture below.

Flat bottom pouches look premium and provide great shelf presence, but they require more film and complex filling machinery.

Bottom gusset pouches , also called standup doypack, offer an excellent balance between aesthetics and cost for lower volumes (fewer than 500g).

Side gusset bags are more economical and efficient for larger volumes (500g–1kg).

Quad seal bags are able to present sharp and square effect for the final filled packages.

2. Align Your Specified Material With Online Stock Bags

Many coffee brands overpay simply because their material specification is more than what they actually need.

For example, when you just need to serve your local customers, the high barrier metallized film bags should be enough to preserve the freshness. On Amazon and alibaba, there are various options of stock bags available covering different materials, bag formats and capacities.

- Stock Material: (Brown/White) Kraft Paper/VMPET/LDPE, Matte BOPP/VMPET/LDPE

- Bag formats: Flat bottom bag, side gusseted bag, quad-seal bag and standup doypack

- Capacities: 100g, 250g, 12oz, 16oz, 500g, 2 pounds and 1 kg available

This way, you do not need to customize your bag with specified materials for these local customers.

When you need to customize your bag with specified materials, staying with the mainstream would be a good choice, such as the most common foil laminate PET/AL/LDPE for roasted coffee beans, which preserve the freshness perfectly, and lower the materials cost, as they are produced in bulk.

The thickness of the materials have to be considered, as thicker film does not mean better protection or better quality. We are here to advise a cost-effective thickness that matches your ideal bag.

Some new emerging materials, like fully recyclable materials and compostable film materials, may come at a higher price than traditional film packages. You are advised to learn about them first, and get the ideas of people who are using them instead of shifting your current packages to these new packages immediately.

3. Simplify Artwork to Reduce Printing Costs

A good appealing and storytelling bag doesn’t mean the artwork needs to be complex. In fact, simplifying design elements can highlight the information you want your customers to pay attention to.

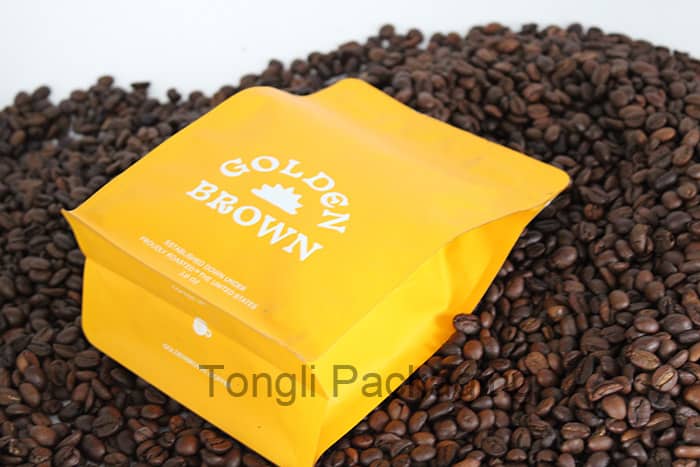

Just take the Gold Brown bag for example. It just uses an attractive yellow background and leave the logo unprinted in white. Further more, it even doesn’t include the product information on the artwork, which just capture the attention of the people who has already had a certain understanding of this brand.

This artwork avoids the CMYK color overlapping and just utilise the spot yellow color, allowing the white color to pop out from the background, so only 3 print cylinders are needed for the front/back/bottom part, and another 3 print cylinders for the side part. Fewer cylinders do not only mean saving serveral hundreds on the printing cylinders, but also it can further reduce the waste in printing procedure, which helps to achieve a more cost-effective finished bag.

4. Unify Your Design System Across SKUs

Many brands lose money because every bag design — origin, blend, roast level — is treated as a separate artwork.

Instead, develop a unified design system where the main structure and layout stay consistent, and only a few elements change:

- Roast level indicator (light / medium / dark)

- Color panel or label

- Text area for coffee origin or tasting notes

Take the below doypack mockup for example, we can see the three mockups are in an unified design. All the top parts are with the same logo, elements, and you can add more identical information of your products here. There are different backgrounds on the front lower part, which tells the different SKUs very easily. All the texts in this area is set in white color, which is able to present concise informaton of each SKU.

This approach allows you to use shared printing cylinders across multiple SKUs, which apparently reduces the cost on print cylinders, and saves the changeover time in printing between different SKUs.

For some SKUs, the order quantity may not be enough to apply unique printing. It should be more cost-effective to use base-design bag, and put stickers on them. In this case, when you order base-design bag in a larger quantity, that will surely be able to get a more favorable price from us.

5. Choose Printing Techniques Wisely

Gravure printing should be cost-effective for larger runs (≥10,000 bags), even though it will need printing cylinders. So when some Skus will be ordered in large quantity and the artwork information stays the same, so you can make printing cylinders and get your order printed by gravure.

When you need to launch new item into the market in short runs or just want to test the market, then it is more wise to choose digital printing, which can be a better choice for orders like 1,000~3,000 bags. Further more, you do not need to pay the cylinders cost, which allows to you narrow your artwork of new item after testing.

Combining both methods strategically keeps your design agile and your cost balanced.

6. Consider Valve and Zipper Placement

One-way degassing valves and zippers are valuable components for a fine coffee package, however they add up in cost. Sometimes, you may consider seriously whether you truly needs them on your products. For wholesale or foodservice packs, you may just skip zippers and rely on tin-ties or clips.

7. Choose Fine-tuned Package Dimension

The denstiy of the roasted beans differs much between different roasters. To hold your aim capacity, you may need to tune the dimension seriously against your own products. Extra dimensions will need more film materials and add up in the unit price.

We have coffee bag samples with different dimensions, which can be shared with you to locate the very best dimension for your own beans. Please keep in mind, even a 5% reduction in film usage across tens of thousands of bags means tangible annual savings.

8. Try to Incorporate Kraft Paper into Your Package

Kraft paper is light-weight, cost-effective, eco-friendly and can be recycled for repeated times. For all the packaging film materials, kraft paper should be considered as the most economical material, with nearly half the price of LDPE film.

Kraft paper is also tough and able to present great standing effect for the final packages. When a kraft paper is applied in the laminate, the usage of LDPE film can be larged reduced, which of couse is going to bring down the unit price of a finished coffee pouch.

9. Do not Make Your Package Too Complex

Many coffee brands equate premium with heavy materials, full metallic prints, golden hight, matte varnish, embossing, hot stamping or other complex finishes. But the modern coffee consumer values authenticity, sustainability, and thoughtfulness more than extravagance.

A minimalist matte pouch with elegant typography and clean storytelling can often feel more premium than a heavily foiled design — and cost half as much.

Premium isn’t about spending more. It’s about expressing value clearly and consistently.

10. Test Before You Move to Mass Production

It is always wise to perform sufficient testing before you move into mass production of your order, as most of the problems happen in an unexpected way. Upon our experience, some customers may have to change the description of their products, as they face some confusion from their customers, and some may have to update their cerificate sign, which may all cause the printed bag not able to work. Further more, you also need some time to see if the customized bag is able to fully fulfill the protection and preseveration purpose for your products in all the life cycle.

Spending more in the test period may really help you avoid the huge lost of unexpected mistakes.

11. Order Smart — Quantity Planning Matters

For the minimum order quantity, we are limited to the supply of film materials. In china market, the film materials are usually supplied in rolls of 6,000 meters long. As the width and thickness are particularly in match with this customized bag, so the film materials may have to be put into stock if your order quantity can not consume the whole roll.

Take the 12oz Gold Brown bag for example, the dimension is W127XH200+Gusset80mm. According to our craftsmanship, the MOQ should be 44,000 pcs. If you order less than this MOQ per artwork, we will have to charge some extra cost as production compensation.

So, when you have several SKUs, you may order the base-design meeting our MOQ policy, and apply stickers over each bag to differentiate the SKUs.

15. Conclusion: Smart Design, Lasting Value

Cost-effective coffee packaging design isn’t about being cheap — it’s about lasting value. When you focus on what truly matters — functionality, brand clarity, and reliable protection — you naturally eliminate waste and unnecessary spending. Every dollar saved on packaging inefficiency can go into better beans, better roasting, or better customer experience.

In the end, the most successful coffee brands don’t chase the lowest packaging price. They master the art of creating maximum value per dollar — with thoughtful design, disciplined testing, and smart partnerships. That’s how real coffee packaging excellence begins — not by spending more, but by designing smarter.