Coffee packaging is a functional system that delivers your products safely to the hands of customers. To make a successful business, nevertheless, coffee packaging should be taken as a decorative afterthought. In contrast, thoughtful ideas should be seriously evaluated, and cautious actions should be brought into reality if you do not want to take the risks of ruining your brand reputation. Upon our experience, one of the most common and costly mistakes coffee brands make is rushing into mass production without sufficient packaging testing.

Whether you are launching a new coffee product, switching suppliers, changing materials, or upgrading your artwork, committing enough testing before mass production is not optional. It is a strategic necessity.

In this post, we will explain why thorough packaging testing matters, what risks it mitigates or eliminates, and how it ultimately saves time, money, and brand reputation.

1. Coffee Is Extremely Sensitive—Your Packaging Must Be Proven, Not Assumed

Coffee is vulnerable to oxygen, moisture, light, and mechanical stress. Even minor packaging flaws can lead to rapid aroma loss, flavor degradation, Clumping or caking of powder or even seal failures during shipping.

On paper, many packaging structures seems “great”. However, in reality, many packages just fail to do the job of a good business.

Only testing—under every circumstances, actual filling, sealing, and transportation conditions—can confirm that your packaging truly protects the product as intended.

2. Package Dimension Can Only Be Validate If Every Procedure Says OK

Package dimension is the first key thing when you customize a bag, because it directly determines whether the packaging will function correctly throughout the entire process—from filling and sealing to transportation and shelf display.

A suitable package dimension will not only ensure it hold target product weight with proper headspace, and present great profle on the shelves. Some customers may prefer a high skinny package for their products, however some may prefer a short-fat effect.

Next, the package will have to run smoothly on filling machines without jamming or wrinkling, otherwise, the dimension may have to be adjusted.

When the products are distributed in the market, more often, the package dimension has to be limited to the height between floors of the shelves.

So, the package dimension can only be validate when it passes the requirements in each and every procedure and it is wise to test before you put the bag into mass production.

That’s why we always take the package dimension as our top priority when we customize a bag for our customers.

3. Material Changes Always Require Validation

Sometimes, the materials of the coffee package may have to be updated to meet the demand in the market, and it doesn’t mean the new materials will certainly work well for your current business.

As a reliable manufacturer of coffee packaging in China for more than 10 years, we have so much experience over the materials and validation problem, and you are welcome to reach us for ideas whenever you want to customize your own coffee bag.

Take this brown kraft paper flat bottom bag for 1 kg coffee for example, the most common film materials is Kraft Paper/VMPET/LDPE triplex laminate.

Some customers may want to switch metallized film to aluminum foil, to improve aroma-preserving property of this kraft paper bag, like Kraft Paper/Al/LDPE. Of course, aluminum foil is of much better barrier property than metallized polyester film, however, aluminum foil is rigid, non-extendable, and dead-fold. The Kraft Paper/Al/LDPE laminate may face the risks of cracking on the aluminum layer when it is folded for several times on the bag-making line, as shown in the video below.

The crack of aluminum foil would cause the final package to lose aroma-preserve property and cause product spoilage in very short time.

So, it is always wise to do a sample order to test the packages in the product life cycle when you need to change the materials for your products.

4. Filling and Sealing Behavior Must Be Verified on Real Equipment

Let’s continue explanation based on above kraft paper coffee bag.

The thickness of each layer will enfluene the final price of a finished bag, and of course the property. When a kraft paper with higher thickness is applied, the thickness of inner LDPE film may be reduced. As the price of LDPE film is nearly double of the price of kraft paper, so the thinner for the LDPE film used, the lower price for the finished bag.

For the stock bags sold on Amazon or Aliexpress, most popular material structure is Kraft Paper 70gsm/VMPET12/LDPE40, as this will help to achieve the lowest price among all kraft paper coffee bags.

However, upon our experience, coffee bag of this Kraft Paper 70gsm/VMPET12/LDPE40 laminate will be hardly workable for the automatic filling and sealing in the production line, as the inner layer is so vulnerable, which may cause the package to break during filliing process.

Under this circumstances, we will update the material structure to Kraft Paper 45gsm/VMPET12/LDPE80, to improve the mechanical property. In some cases, this bag can not still ensure zero-failure in all the life cycle. We may have to update the materials into Kraft Paper 45gsm/VMPET12/PA15/LDPE60 to resist any possible stress.

This step ensures smooth, stable mass production instead of emergency troubleshooting on the production floor.

5. Transportation Testing Prevents Costly Market Failures

Coffee packaging must survive under the circumstances in transport, like

- Pallet stacking

- Long-distance shipping

- Vibration and compression

- Drops during handling

You will need to perform essential test like drop testing, compression testing, burst testing to ensure the bag able to resist any possible stress. In our manufacturing plant, we incorporate these tests into our quality control work, to ensure each order is produced against your requirements. Still, you are advised to perform tests at your own site, to discover potential problems durign your usage, so we can improve our craftsmanship and output qualified bags for your business.

Sometimes, accidents still happen beyond your expect, allow me to share one of our cases.

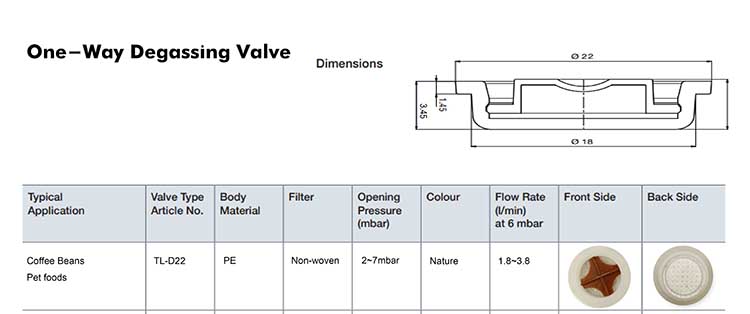

The degassing valve TL-D22 can only release the inside air when the inner air pressure is 2~7mbar higher than the environment. This pack is going to hold 1 kilograms of roasted beans, which may emit a large amount of CO2 in short time, and it will cause the package to expand.

When the expansion cause the degassing valve facing tightly against the other package, it will cause the air-venting blocked, and continous emission of CO2 will further increase the inner pressure to a level that will burst the package.

Failing to test transport performance can result in leaks, returns, distributor complaints, and damaged retailer relationships.

6. You May Not Know How Consumers Communicate Through Your Package

The coffee package is an important communicaton method between you and the customers, and more often, you may do not know how your consumers communicate through your packages.

Take the rip zipper for example, most consumers rip from the correct side and direction and make the bags easy to open.

However, some may just rip any way they like, such some left-handed consumers, they may rip the wrong way.

Could you understand how this bag is ripped?

Actually, this zipper was ripped from back side, with unimaginable force.

So, when a rip zipper is applied on a package, rip instruction may still be essential to correct some wrongly open of your coffee packaging.

It is difficult for us to stand in every customer’s shoes and think about how to use our products. That’s why you should spend time testing your coffee packaging when you launch a new one into the market.

7. Artwork & Information May Need To Be Updated

Consumers communicate with you through the packaging and artwork. No matter how seriously and carefully you plan on the artwork, how thoughtfully you work on each element, and how delicately you tune every sentence, you may find you artwork need to be updated after the consumers’ feedback.

So, to avoid your printed bag not able to be used in large quantities, it is always wise to test the market with a minimum order quantity the supplier can offer. When you are sure you locate the best artwork to your branding, then you can move into mass production.

8. Regulatory and Food Safety Compliance Cannot Be “Fixed Later”

Coffee packaging must comply with food contact regulations, migration limits, and labeling requirements in your target markets.

Testing before mass production helps ensure:

- Materials meet food-grade standards

- Inks and adhesives are safe and stable

- No unexpected odor transfer occurs

If compliance issues are discovered after mass production, the consequences can include recalls, legal exposure, and permanent damage to brand credibility.

Of course, as a reliable manufacturer for more than 15 years, we will issue the certificate of our materials used to comply with certain food safety regulations.

9. Testing Costs Less Than Rework—Every Time

Some brands hesitate to invest in testing because they view it as an added cost. In reality, testing is insurance.

Compare the cost of:

| Testing | Rush into mass production |

| Pilot runs Lab testing Transport simulation | Scrapped inventory Emergency air freight Customer compensation Relaunch delays |

Testing before mass production is always the lower-risk, lower-cost option.

10. Testing Builds Confidence Across the Supply Chain

When the customers reach us and customize a bag, we will spend much time figuring out the true demand of the packages.

- How are they going to fill the bags?

- How do they sterilize their products?

- Do they distribute nationwide,?

- The expected shelf life?

- Food safety regulations?

- How is about their artwork?

- ………………………………….

From a business perspective, we surely hope each and every of our customers will have a great business, that’s the only way we can grow our business. Testing reduces potential risks and strengthens long-term partnerships with us, as it is a reliable way to move forward to bigger success.

Conclusion: Test First, Scale With Confidence

Mass production amplifies everything—good decisions and bad ones alike. When it comes to coffee packaging, testing is the difference between controlled scaling and costly surprises.

By committing enough testing before mass production, you:

- Protect your coffee quality

- Reduce operational risk

- Safeguard your brand reputation

- Save money in the long run

In coffee packaging, testing is not about caution—it is about professionalism.