Block bottom paper pouches have become a popular choice for premium nut packaging, particularly for products like bamdam nuts. This structure features a natural paper exterior that gives the pouch a clean and authentic look, while the sturdy multi layer design ensures reliable performance throughout the supply chain. The strong paper body presents a warm and refined appearance, making the nuts feel closer to their natural origin.

Built with protective layers, the pouch shields the nuts from moisture, oxygen, and external contaminants, helping maintain their crispness, aroma, and overall freshness. The block bottom design allows the pouch to stand firmly on shelves, enhancing display impact, and the wide top opening makes both filling and final sealing smooth for production teams.

From a branding point of view, block bottom paper pouches provide an elegant and natural surface for printing. The paper material supports clear graphics and thoughtful storytelling, allowing brands to highlight origin, flavor notes, and nutritional details. The overall presentation delivers a sense of quality and reliability that helps customers feel confident in their purchase.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

In this post, we will introduce details about the exact film structure used in the 250g bamdam nuts.Hope it is helpful for people in need.

Packaging Foil Materials

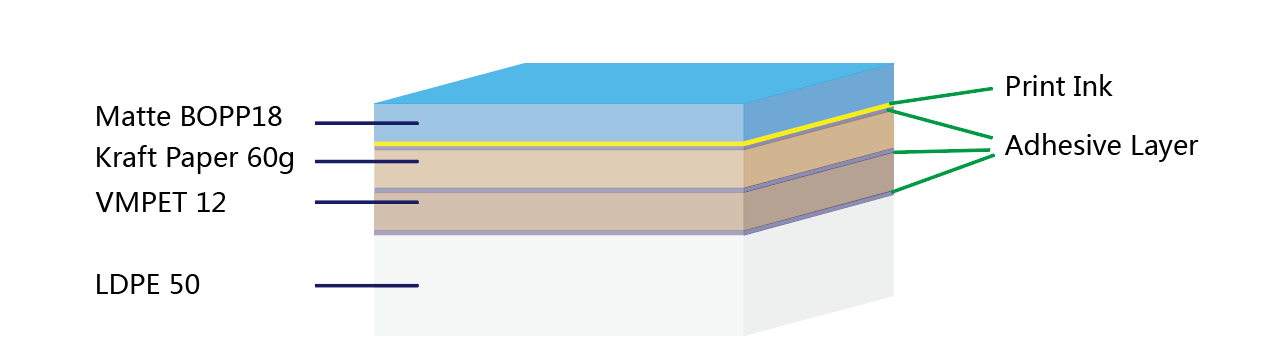

The figure below shows the composition structure of this laminated foil material used to convert this block flat bottom dry nuts pouch.

It is constructed with four layers. The outer layer is an 18 micron Matte BOPP film that serves as the print substrate. This is followed by a 60 gram Kraft Paper layer, then a 12 micron VMPET layer that enhances barrier performance. The innermost layer is LDPE, which functions as the sealing layer. The thickness of the LDPE layer can be adjusted according to the protection and strength needed for a 250 gram pack of bamdam nuts.

MatteBOPP Film

Matte BOPP, or matte biaxially oriented polypropylene, is a polymer film with a soft, low gloss surface that diffuses light rather than reflecting it. With its gentle matte appearance, Matte BOPP is widely used on the outer layer of packaging to enhance visual appeal and give products a more modern and premium look.

Its main functions in food packaging are:

- Enhancing appearance – The matte finish reduces glare and provides a premium, modern, and natural look that attracts consumers.

- Printability – Matte BOPP serves as an excellent substrate for high quality printing, allowing for detailed graphics, branding, and product information.

- Printability – Matte BOPP serves as an excellent substrate for high quality printing, allowing for detailed graphics, branding, and product information.

- Moisture and chemical resistance – While not a full barrier film, Matte BOPP helps reduce moisture and external contamination when used in multi-layer laminates.

KraftPaper Film

Kraft paper is a lightweight, cost effective, and recyclable material commonly used for roasted bean and dried food packaging. It can be strengthened with laminates or additional layers to enhance barrier performance.

Many businesses are returning to paper based packaging to connect with environmentally conscious customers. Kraft paper is biodegradable and recyclable, making it a highly eco friendly choice that helps brands reduce their environmental footprint. It also offers excellent flexibility for customization, allowing for a wide range of printing effects and design styles.

Research consistently shows the rising popularity of kraft paper packaging. Beyond its sustainability advantages, many businesses choose kraft paper for its dependable strength. It can withstand challenging industrial conditions such as moisture, heat, and cold, making it suitable for a wide range of environments and demanding supply chains.

VMPET Film

VMPET film is short for vacuum metallized polyester film, created by depositing a thin layer of aluminum onto a PET substrate under vacuum conditions. This process forms a bright, metallic looking film that is widely used in flexible packaging and stand up pouch applications.

In food packaging, VMPET is commonly used in pouches for snacks, nuts, dried fruits, coffee, tea, and confectionery. Its metallic layer provides an attractive appearance while also offering strong barrier performance, making it a preferred choice for products that need extended freshness.

The key function of VMPET is its excellent resistance to oxygen, moisture, and light. These barrier properties help protect food from oxidation, aroma loss, and quality deterioration. VMPET also adds stiffness to the structure, improves puncture resistance, and enhances shelf presence, making it an essential component in many high performance laminated packaging materials.

LDPE Film

LDPE film, short for low density polyethylene film, is the most commonly used inner sealing layer in multi layer flexible packaging across a wide range of applications. It provides excellent heat sealability, flexibility, and chemical resistance, ensuring that products remain securely protected during storage and transportation. Its softness and conformability also make it ideal for creating reliable seals in pouches, bags, and other flexible packaging formats.

Why choose LDPE?

- Low Cost: LDPE is one of the cheapest plastics available, making it a popular choice for a wide range of applications.

- Flexibility: LDPE is highly flexible, allowing it to be easily formed into a variety of shapes and sizes.

- Toughness: LDPE is highly resistant to impact, making it suitable for use in applications where it may be subjected to mechanical stress.

- Chemical Resistance: LDPE is resistant to many chemicals, making it suitable for use in applications where it may be exposed to harsh chemicals.

- Recyclability: LDPE is recyclable, making it an eco-friendly choice.

These 4 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. The resulting material is commonly referred to as MatteBOPP/KraftPaper/VMPET/LDPE foil.

Great Standup Effect

This multi layer structure, combining Matte BOPP, Kraft Paper, metallized PET, and LDPE, gives the pouch an excellent stand up performance. The reinforced block bottom provides a stable base, allowing the bag to remain upright on shelves, even when partially filled.

This not only enhances product visibility and shelf presence but also makes handling, filling, and display easier for both retailers and consumers. The sturdy construction ensures the pouch maintains its shape, giving a premium and reliable feel while effectively showcasing the product inside.

Excellent Airtight Property for Zipper lock

The inner LDPE layer bonds tightly with the zipper, ensuring a strong, airtight seal. This makes it convenient for customers to repeatedly open and close the package while preserving the freshness of the contents over time.

Our quality control team carefully monitors the zipper’s sealing performance. You can see a detailed demonstration of the testing process in the video below.

Mechanical Property

This reinforced laminated foil offers excellent mechanical strength, with key standard properties as listed below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order based on customer requirements.

Drop Test

As part of our routine quality checks, we evaluate the durability of each bag to ensure it meets the specific standards required by our clients. Each order is subjected to a drop test, with criteria tailored to the individual customer’s performance expectations.

In this procedure, the bag is dropped three times from a height of 1.6 meters. Following the drops, we thoroughly inspect the bag to verify that it has withstood the test without any damage.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, MatteBOPP/KraftPaper/VMPET/LDPE foil laminate will be able to meet most of the requirements for platinum chips. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 1.25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.36 |

More Sustainable Materials Options

With the increasing environmental burden caused by fossil-based polymer waste, the demand for sustainable packaging continues to rise. Recent studies in the detergent market indicate that consumers are becoming more willing to purchase products that clearly demonstrate a commitment to environmental responsibility.

Compostable Packaging Materials

This kraft paper PLA+PBAT film pouch was burid into soil on Nov 26, 2021, and one and half years passed, dated on August 17, 2023, we are going to check the degradation process of this compostable foil pouch. Actually, all the outside layer kraft paper degraded into inorganic elements without any things left. However, the inner PLA+PBAT film did not degrade into nutrients. Surely, the activity of micro-organism is keeping a lower level for soil conditions and surely it will need a longer time to degrade. We got it well buried again, and surely, we will keep you posted with the progress of this composting test.

We have developed several compostable foil materials that can be intended for roasted sunflower seeds, with the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the higher cost of compostable foil materials, fully recyclable sachets and roll films are quickly becoming the preferred choice in the market due to their cost-effectiveness and suitability for lightweight packaging.

Thanks to ongoing advancements in PE film barrier technology, recyclable foil-free laminates can now provide reliable protection for products such as sunflower seeds by effectively blocking moisture. For applications requiring even stronger performance, a PVA coating can be applied to LDPE or HDPE films to further improve moisture resistance. In addition, integrating an EVOH barrier layer into biaxially oriented PE (BOPE) films significantly enhances oxygen barrier properties, making this structure an excellent solution for modern flexible packaging.

If you have any questions or would like further information about our juice pouch packaging solutions, don’t hesitate to get in touch.

Wishing you a wonderful day!