500g premium puppy food packaging typically uses a multi-layered, high-barrier aluminum foil structure, which not only enhances the product’s freshness but also makes the packaging more stable, professional, and suitable for long-distance transportation or high-temperature environments.

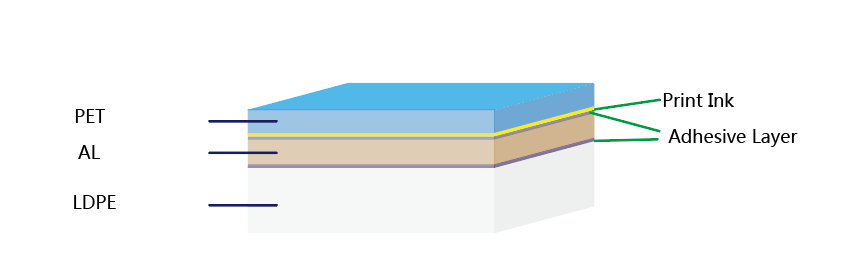

Common Structure: PET/AL/LDPE

- PET (Polyester Film) – 12μm

Provides bag stiffness and printing effect; Bright colors, scratch resistant;Protects outer pattern from fading

- AL (Aluminum Foil) – 7μm

Core high-barrier layer; Completely blocks light, oxygen, and moisture; Effectively preserves grain aroma, preventing oxidation and spoilage

- LDPE (Low-Density Polyethylene) – 100μm+

Inner layer is a food-grade direct contact surface; High heat-sealing strength, less prone to bursting;Soft and resilient, easy to open and reseal

Some high-end brands also add a second layer of PET (PET/AL/PET/LDPE) to further enhance bag stiffness and puncture resistance.

Key words

- Strong load-bearing capacity

- Superior packaging and display effect

- Larger loading capacity and higher space utilization

- Stronger sealing performance, less prone to breakage

- More upscale appearance, beneficial to brand positioning

Packaging Foil Materials

The image below shows the composition of the laminated foil material used to manufacture this type of flat-bottomed bag.

It is made of three layers, with the outside PET film 12 microns working as the print substrate film, the AL film 12 microns working as the middle barrier layer, and finally, the LDPE film working as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of grams.

Ok,let’s get into a deeper understanding of each substrate film material.

PET Film

PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing

AL film

AL Film, short for Aluminum Foil, is one of the most important barrier materials used in flexible packaging. It provides an excellent barrier performance against oxygen, moisture, light, and odors, which helps extend the shelf life of sensitive products such as food, coffee, snacks, pharmaceuticals, and chemicals.

Aluminum foil has a stable structure, is highly puncture-resistant, and maintains its barrier properties even in thin gauges. It also offers strong heat resistance, light-blocking capability, and printability when laminated with other films such as PET, BOPP, or PE.

Because of its outstanding preservation ability and high-quality appearance, AL-laminated packaging is widely used in premium-grade flexible packaging.

LDPE film

LDPE (Low Density Polyethylene) is a soft, flexible, and highly versatile packaging material widely used in the flexible packaging industry. It is known for its excellent sealing performance, good impact resistance, and high flexibility, making it ideal as an inner-layer film in laminated structures.

LDPE provides good moisture resistance, transparency, and smoothness, allowing products to be filled easily while maintaining strong and reliable heat seals. It is commonly used in food packaging, frozen products, detergents, agricultural supplies, and various consumer goods.

In laminated packaging, LDPE is often combined with other materials such as PET, BOPP, or AL to enhance durability, barrier performance, and product shelf life. Typical structures include PET/LDPE, PET/AL/LDPE, and BOPP/LDPE.

Because of its cost-effectiveness, safety, and excellent sealing properties, LDPE remains one of the most widely used materials for pouch-making and film packaging.

Great Standup Effect

You can check the quality and standing effect of the bags through the following video.

Excellent Airtight Property for Zipperlock

This single-track plastic zipper is applied onto the kraft paper doy pack, with the back and front parts well melted to the inner layer of the doy pack. It enables the package to be repeatedly opened and closed with great airtight properties

Mechanical Properties

The PET/AL/LDPE laminate offers excellent overall mechanical performance due to the synergy of each layer:

High Tensile Strength

The PET layer provides strong tensile strength and dimensional stability, ensuring the package maintains its shape and resists stretching during processing and transportation.

Excellent Puncture and Tear Resistance

The aluminum foil (AL) layer enhances puncture and tear resistance, making the structure suitable for products that require strong protection against sharp or irregular contents.

Good Flexibility and Sealability

The LDPE layer contributes softness and flexibility while offering strong heat-seal performance, ensuring secure seals and preventing leakage even under stress.

Superior Barrier and Mechanical Durability

The combination of PET, AL, and LDPE offers an excellent balance of stiffness and flexibility, allowing the pouch to withstand mechanical stress, bending, and handling without compromising package integrity.

Stable Performance During Filling and Transportation

The laminate structure maintains mechanical stability under various filling speeds and ensures reliable performance throughout storage and shipping

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

More Sustainable Materials Options

With the increasing environmental burden caused by fossil-based polymer waste, the demand for sustainable packaging continues to rise. Recent studies in the detergent market indicate that consumers are becoming more willing to purchase products that clearly demonstrate a commitment to environmental responsibility.

Compostable Packaging Materials

Compostable packaging is made from plant-based fibers such as cellulose, or bio-based resources like corn starch, cassava, and sugarcane. The resins derived from these materials are commonly referred to as biopolymers, which can naturally decompose into inorganic elements through the action of algae, bacteria, and other microorganisms.

By adopting compostable packaging, brands demonstrate their commitment to sustainability while satisfying growing consumer demand for environmentally responsible products. It’s a practical step toward a greener future without compromising product quality or aesthetics.

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Ok, let’s end here, you may reach us if you have any questions, nice day.