As shown in the image above, this is a flat bottom pouch with a tab zipper, designed to hold up to 500 grams. Flat bottom pouches are widely used in food packaging due to their excellent stability, large display area, and convenient resealable feature.

As a well-established flexible packaging converter based in Qingdao, China, we make optimal use of the film materials available in the market, as listed below.

- Fossil-Based Chemical Polymer Films

- Aluminum Foil Metal Sheets

- Vacuum-Metalized Film Substrates

- Ceramic Film Substrates

- Plant-Based Biopolymer Materials

- Biodegradable Film Materials

- Compostable Substrate Films

- Fully Recyclable Substrate Films

In this post, we take a closer look at the specific film structure used in our 500g flat-bottom coffee bags. We hope this breakdown will provide a practical reference and inspiration for your own packaging development.

Ok, let’s get into the details of this flat bottom coffee bag!

Packaging Foil Materials

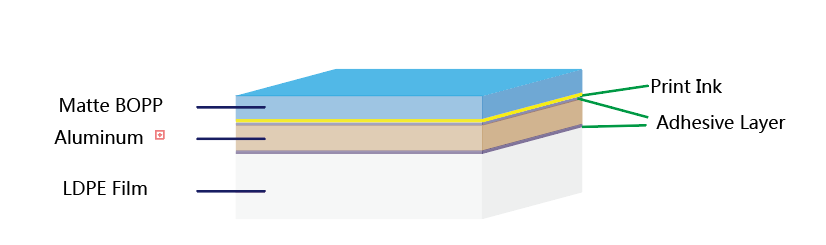

The figure below shows the composition structure of this laminated foil material used to convert this flat bottom coffee bag.

Matte BOPP18, is short for matte finish biaxially orientated polypropylene film with most common thickness 18 microns (equals to 0.72 gauge). Compared to glossy BOPP film, it is able to achieve the final package with a fine matte visual appearance for the package at a lower cost.

Aluminum foil is a thin, pliable sheet of aluminum alloy that is often used for wrapping and covering food during cooking. It is made by rolling large slabs of aluminum until they are less than 0.2 millimeters thick, and then solidifying the molten alloy between water-cooled rollers. During the final rolling process, two layers of foil are passed through the mill at the same time, resulting in one shiny side and one dull side.

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. It is often used for manufacturing plastic goods like cling wrap, juice containers, orthotics, and prosthetics.

The final thickness for this foil laminate should be 120 microns, with tolerance +-5%. and the toughness will be enough to finalize good standing effect.

Great Standup Effect

Through the below video, you can see the bag with greater stiffness and standup straight effect

Excellent matte finish effect

A layer of matte lacquer coating is applied to the outer layer of this foil laminate. In some cases, poor workmanship can result in subtle hidden lines appearing on the surface.

With our improved process, we are now able to achieve a premium matte finish with exceptional surface quality,completely free of hidden lines-while ensuring no impact on filling performance at the customer’s plant.

Excellent Airtight Property for Zipper lock

The tab zipper, which is also called rip zipper, which enables the coffee pouch easily torn from the tab place, in a straight-line effect.

Serious measures are taken in our QC work to check the airtight properties for the inner zipper, and you are advised to have a further understanding of this test progress through the video below.

Mechanical Property

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

Drop Test

In our daily QC work, there is an more easy and reliable method to check if the coffee bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, distribution. We perform drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to drop the filled coffee bag from 1.6m high, for 5 times.

You are advised to watch the video below.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

More Sustainable Materials Options

As plastic pollution continues to intensify, an increasing number of brands are actively seeking more sustainable packaging solutions, such as compostable packaging, recyclable mono-material packaging, and plant-based material packaging. These alternatives have proven to be significantly more eco-friendly than traditional multi-layer packaging, which is often extremely difficult to recycle.

Home compostable film material packages

Our company has developed multi-layer foil stand-up pouches that are compostable under both home/garden and commercial composting conditions.

For this test, I will bury the pouches directly in natural soil, where the composting process is expected to take longer. This is because factors such as microbial density, moisture levels, and temperature play a critical role in the composting rate.

We will closely monitor the composting progress throughout the test period and will keep you regularly updated with our observations and results.

Mono Materials Recyclable Pouch Packages

Mono-material pouch packaging is truly recyclable because it can be easily reprocessed into plastic granules and used again for new applications.

In contrast, traditional multi-layer laminates, for example PET/LDPE structures, are difficult to recycle. PET and LDPE are completely different materials and cannot be melted or reprocessed under the same conditions, which makes separation costly and inefficient. This is the key reason why mono-material pouch formats are gaining strong traction in the packaging industry and earning a positive reputation among consumers.

Now it’s the end. You are welcome to reach us if you have any questions regarding juice pouches. Have a nice day.