A wide variety of packaging bags have greatly enhanced the convenience of our daily lives. Pillow bags are popular for their unique style and practicality. They are often used in industries like food, where they are convenient for transport, storage, and display.

So, what materials are pillow bags made of?

Let’s take a closer look at the details of pillow bags.

Packaging Foil Materials

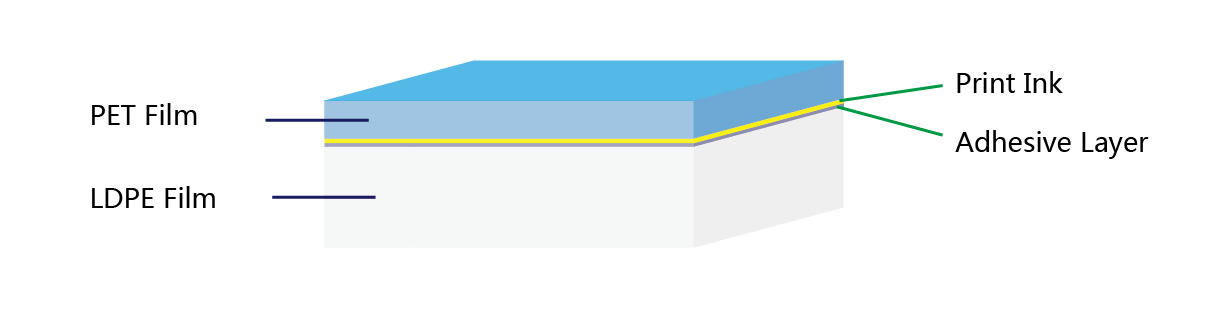

The film material for the chocolate balls consists of two layers: a printed layer made of PET film and an inner sealant made of LDPE film. The thickness of the LDPE film needs to be adjusted based on the packaging requirements of a 20g chocolate snack.

Next, we will further discuss the film material used for each substrate.

PET Film

PET film (sometimes also called BOPET film) is one of the most commonly used printing substrates in the flexible packaging industry. It offers excellent optical clarity, high gloss, good chemical resistance, stable mechanical strength, outstanding dimensional stability, and excellent printability. It can present customer artwork in a high-quality manner and provide excellent mechanical strength to the final packaging.

LDPE Film

LDPE, or low-density polyethylene (LDPE), is the most commonly used inner seal layer for packaging bags, providing sufficient sealing strength and airtightness. LDPE film is flexible, flexible, and resistant to damage. Its high transparency makes it easy to display products. This makes it popular in food packaging, and it’s often found in packaging for biscuits, candies, and other products.

LDPE film also offers excellent moisture resistance, effectively blocking moisture and protecting product quality. It also has relatively good chemical resistance, showing some tolerance to many common chemicals. However, LDPE film also has limitations, such as relatively low mechanical strength, making it susceptible to deformation and even damage when subjected to significant external forces. Furthermore, its oxygen barrier properties are not ideal, and for packaging oxygen-sensitive products, it may need to be combined with other materials to enhance barrier properties.

Mechanical Property

The mechanical properties of PET/LDPE materials are as follows.

The PET layer has high tensile strength and modulus, making the bag less susceptible to tearing when subjected to certain tension. For example, when handling a heavy bag, the PET layer can withstand the tension generated by the weight of the items, preventing the bag from tearing at the handles or other stress-bearing areas.

The tensile strength of the LDPE layer is lower than that of the PET layer, but its presence increases the overall flexibility of the bag. This means that when subjected to a small tensile force, the bag can be stretched to a certain extent without breaking immediately, allowing the bag to adapt to a certain range of external force changes.

When producing these chocolate ball pouches, we prioritize performance. Our quality control system implements stringent measures to ensure that every order meets expected standards.

In short, drop testing a filled package is one of the most reliable ways to verify whether it will break under sudden, severe impact. You can watch a similar video.

Sure, there are reinforced foil structures available for more pillow packages

- Kraft Paper/LDPE

- PET/VMPET/LDPE

- PET/PA/LDPE

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The table below shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/BOPA/LDPE foil laminate will be able to meet most of the requirements for household laundry detergent liquids. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.85 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.2 |

Technical Data Sheet of 20g Chocolate Balls Pillow Pouch

Here, we attach the specification sheet of this 20-gram chocolate balls bag based on foil laminate PET/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Learn more about this foil laminate on our company website.

Sustainable Materials Option

With the growing burden of fossil-based polymer materials being discarded into our environment, the demand for sustainable packaging has reached an unprecedented level. This shift is driving businesses to adopt more eco-friendly practices. Recent studies of the juice market show that consumers are increasingly inclined to choose products that demonstrate a commitment to environmental sustainability.

Compostable Packaging Materials

Compostable packaging materials are often confused with biodegradable ones, as the difference is not always well understood. In simple terms, compostable materials are a type of biodegradable material, but with an added benefit: when they break down, they leave no harmful residues in the environment.

For our factory’s applications, customers can consider biodegradable and compostable materials as essentially the same.

Our biodegradable packaging is derived from renewable biomass sources such as maize starch, cassava, sugarcane, and plant-based fibers like cellulose. The resins produced from these raw materials are known as bio-polymers. Under the action of microorganisms such as bacteria and algae, these bio-polymers naturally decompose into harmless inorganic substances.

Now it’s the end. You are welcome to reach us if you have any questions regarding laundry detergent liquid screw cap pouches. Have a nice day!