Stand-up pouches have become a leading packaging choice for juice products in today’s market. By combining different polymers and biopolymer films, these pouches provide excellent protection throughout distribution while remaining cost-effective. In addition, their full-surface printability allows for creative artwork and detailed product information on every side of the pouch, enhancing both brand visibility and consumer appeal.

Juice spout pouches, a special type of stand-up pouch, are widely favored for their convenience and practicality. But what materials are they typically made from?

We are devoted to creating story-telling standup juice bags that increase product sales. In this post, we will analyze the exact foil materials of this 150ml juice standup bag, which assists this juice manufacturer in greater success in their market.

With the rise of environmental regulations and growing consumer awareness, the demand for sustainable packaging has become increasingly urgent. The spouted pouch introduced in this article features a mono-material recyclable design that balances environmental responsibility with commercial value. It not only helps brands establish a green image but also enhances their competitiveness in the market.

Ok, let’s get into the details of this standup spout bag.

Packaging Foil Materials

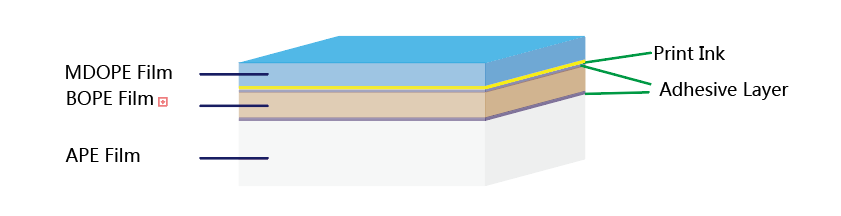

The figure below shows the composition structure of this laminated foil material which is used to convert this standup juice bag.

The outside MDOPE film serves as the print substrate film, the middle reinforced layer is the second BOPE film, and the inner sealing layer is the APE film. It is composed of triplex layers.

Next, let’s get into a deeper understanding of each substrate film material.

MDOPE Film

It’s a polymer film that’s made by heating it to a temperature just below its melting point and stretching it in a specific direction. The film is blown vertically into a bubble, then stretched in the machine direction by rollers that rotate at different speeds. Finally, the film is cooled and annealed to relieve stress and set its properties.

MDOPE is used in packaging for food, beverages, and personal hygiene items. It’s also used in construction, agriculture, and automotive because it’s durable and resistant to UV rays, tears, and punctures. MDOPE has a lower carbon impact than other materials and is recyclable, making it a preferred choice for packaging. MDOPE films can also be coated with PVA to improve their barrier function for gases and small molecules, which can help protect products with high oil content, like meat, spices, and bread.

BOPE, or Biaxially Oriented Polyethylene, is a flexible plastic film made from polyethylene (PE) using a blown process.

This process involves stretching the plastic sheeting in two directions, which results in a material with many advantages:

- Strength: BOPE is stronger and has higher tensile and impact strength than PE film

- Transparency: BOPE is clearer and has higher gloss

- Heat sealing: BOPE has excellent heat sealing performance, with an initial heat sealing temperature as low as 85°C and a strength that can be 1.5 times that of traditional PE film

- Tearing: BOPE has good tearing performance, which can make packaging products easier to tear and more convenient to use

- Recyclability: BOPE is 100% recyclable because it’s made from a single polymeric family, polyethylene, which is preferable to mixed material products and laminates

APE Film

APE is intended to describe the low density polyethylene film with a layer of PVA (Poly-vinyl-alcohol) coating.

Polyvinyl alcohol (PVA) coating is a film coating made from a synthetic, water-soluble polymer that is non-toxic and biodegradable. PVA is also known as PVOH or PVAl. It is often used in pre-mixed coating formulations, but its properties can be adjusted to meet specific needs during development.

The customer artwork is printed reversely on the inner side of the first PET film layer in the gravure printing system. Then, these 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Usually, we describe the finished laminate as MDOPE/BOPET/APE foil. So, how does this foil structure perform when it is intended for stand-up juice bags? Will it break during the transit?

Great Standup Effect

MDO PE has high strength, especially in terms of puncture resistance and tear resistance. This makes it play an important role in some scenarios where high packaging strength is required, such as industrial packaging bags, which can effectively protect the items inside the bag from being pierced by sharp objects from the outside.

BOPE has higher strength. Its tensile strength is 2 – 8 times that of traditional PE films, and its puncture resistance is 2 – 5 times that of ordinary PE composite films. This high strength enables BOPE to withstand greater pressure and external impacts during the packaging process, reducing the risk of package breakage.

The video below shows well the stand-up effect of this 150 ml juice stand-up sachet.

Mechanical Property

The spout pouch is designed to protect juice products throughout filling, transit, and distribution. Even under unexpected shocks during delivery or accidental falls from store shelves, the pouch must remain intact. Imagine the consequences of a leaking package—contaminated cartons, stained floors, and unnecessary product loss.

That’s why the mechanical strength of our 150 ml juice stand-up pouch is a top priority in our manufacturing process. We enforce strict quality control measures to ensure every order meets the highest standards of performance.

One of the most reliable methods to validate this is the drop test on filled pouches, which simulates sudden impact and confirms that the package can withstand sharp external forces without bursting.

Here, we are going to fill 150ml water, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The juice product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of juice products. The table below shows the typical value of the WVTR and OTR of this triplex foil laminate MDOPE/BOPE/APE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

It is clear to customers that this foil laminate does not provide excellent barrier performance, as it lacks any true high-barrier film layer. For brands with stricter requirements regarding the flavor retention and freshness of their juice products, a foil laminate with enhanced barrier properties becomes essential.

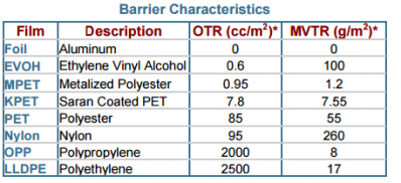

In most cases, a layer of vacuum-metalized film, aluminum foil, or clear AlOx-coated polyester film is incorporated into multi-layer foil structures to achieve the necessary protection. The following table provides a comparison of the typical moisture vapor transmission rate (MVTR) and oxygen transmission rate (OTR) values of commonly used substrate film materials.

Technical Data Sheet of 150ml juice stand up bag

Here, we attach the specification sheet of this 150ml juice standup sachet based on foil laminate MDOPE/BOPE/APE

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this MDOPE/BOPE/APE laminated foil, you may just read here.

Sustainable Materials Option

With the growing burden of fossil-based polymer materials being discarded into our environment, the demand for sustainable packaging has reached an unprecedented level. This shift is driving businesses to adopt more eco-friendly practices. Recent studies of the juice market show that consumers are increasingly inclined to choose products that demonstrate a commitment to environmental sustainability.

Compostable Packaging Materials

Compostable packaging materials are often confused with biodegradable ones, as the difference is not always well understood. In simple terms, compostable materials are a type of biodegradable material, but with an added benefit: when they break down, they leave no harmful residues in the environment.

For our factory’s applications, customers can consider biodegradable and compostable materials as essentially the same.

Our biodegradable packaging is derived from renewable biomass sources such as maize starch, cassava, sugarcane, and plant-based fibers like cellulose. The resins produced from these raw materials are known as bio-polymers. Under the action of microorganisms such as bacteria and algae, these bio-polymers naturally decompose into harmless inorganic substances.

We produce premium-quality compostable stand-up sachets and rolls designed to meet the unique requirements of each product. If you are interested in sustainable packaging solutions, we would be happy to share more ideas with you.