This is flat bottom bag with a capacity of 1.68kg. With the progress of production technology, people’s quality of life is also increasing. The following are the advantages of this bag type in the supermarket.

- Excellent display effect

The eight-side seal bag forms a three-dimensional square shape after molding, which can stand upright on the shelf with a large front display area. - High space utilization rate

The three-dimensional structure makes the bags neatly arranged on the shelf. It can be closely arranged to save shelf space, and the upright placement reduces the problems of tipping over and messy stacking, improving the overall neatness of supermarket shelves. - Strong practicality

The bag is designed with a handle for easy taking and carrying by consumers; the sealed structure of the eight-side seal also provides better moisture and leakage resistance, ensuring the storage quality of laundry powder and reducing the number of product returns to supermarkets due to moisture damage.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are devoted to creating story-telling flat bottom soap powder bag that increase product sales.

Ok, let’s get into the details of this flat bottom soap powder bag.

Packaging Foil Materials

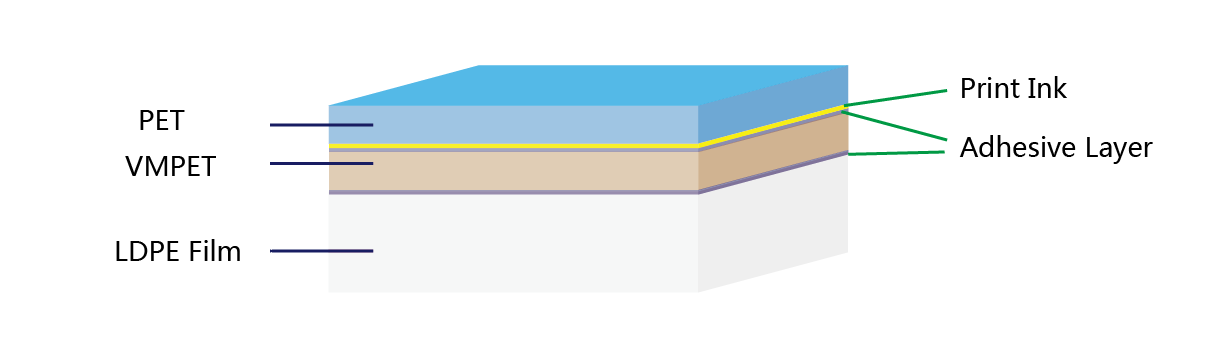

The figure below shows the composition structure of this laminated foil material used to convert this flat bottom soap powder bag.

It is made of triplex layers, with the outside PET film 12 microns working as the print substrate film, the VMPET film 12 microns working as the middle barrier layer, and finally, the LDPE film working as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of 1.68kg soap powder.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So, whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

VMPET Film

VMPET film is short for vacuum metallized polyester film, that is achieved under vacuum conditions to deposit a thin layer of aluminum atoms onto the surface of PET (polyester) film substrate, and finally realize a bright metallic film that is widely used in flexible packaging and standup pouch packages.

Vacuum metallizing, also known as vacuum metallization, is a manufacturing process that coats a metal onto a non-metallic substrate in a vacuum chamber through evaporation. It’s a type of physical vapor deposition (PVD).

LDPE

LDPE is made from long chains of ethylene molecules called monomers and has a chemical formula of (C2H4)n. It has a density range of 917–930 kg/m3 and a lower melting point than other types of polyethylene, such as high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE). These properties make LDPE more flexible and easier to process. LDPE can also withstand a variety of temperatures without leaking toxins and repels microorganisms.

LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. However, the FDA does not consider recycled LDPE to be safe for food usage. You can recognize LDPE on products by the number four in a triangle, usually on the bottom or side of the item.

These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/VMPET12/LDPE foil.

Great Standup Effect

Through the below video, you may learn the standing effect when soaps are filled into the flat bottom bag based on this laminated foil PET12/VMPET12/LDPE95.

Excellent Airtight Property for Zipper lock

This single-track plastic zipper is designed for flat-bottom bags and is firmly sealed to the inner LDPE layer. It allows the pouch to be opened and closed repeatedly while maintaining excellent airtightness. This helps keep the soap fresh for a long time after the package is first opened.

Serious measures are taken in our QC work to check the airtight properties for the inner zipper, and you are advised to have a further understanding of this test progress through the video below.

Mechanical Property

The package will protect soap in filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the package will never be allowed to break.

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order based on customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

Drop Test

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/VMPET/LDPE foil laminate will be able to meet most of the requirements for platinum chips. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 1.25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.36 |

More Sustainable Materials Options

With the growing environmental burden caused by discarded fossil-based polymer materials, the demand for sustainable packaging has reached an unprecedented level. Recent market studies show that consumers are increasingly inclined to purchase products from brands that demonstrate a commitment to environmental responsibility. As a result, adopting eco-friendly packaging has become not only a sustainability initiative but also a strategic advantage for forward-thinking businesses.

Compostable Packaging Materials

Compostable packaging is made from plant-based fibers such as cellulose or biomass materials including corn starch, cassava, and sugarcane. The resins derived from these renewable resources are known as biopolymers. Under the action of algae, bacteria, and other microorganisms, these biopolymers can break down naturally into inorganic elements, leaving no harmful residue.

- BOPLA/PLA

- PT/PLT

- Kraft Paper/PLA

- Kraft Paper/BOPLA

- PT/MPT/PLA

- Metallized Paper/PLA

- Metallized Paper/PT/PLA

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable material sachets and roll films are becoming increasingly popular in the market, offering a more affordable solution for lightweight product packaging.

With continuous improvements in the barrier performance of PE-based films, recyclable foil-free laminates can now effectively protect sunflower seeds from moisture. A PVA coating layer can be applied to the surface of LDPE or HDPE film to further enhance moisture resistance. Additionally, EVOH can be incorporated into biaxially oriented PE film-commonly known as BOPE in the flexible packaging industry-to significantly boost oxygen barrier performance.

Now it’s the end. You are welcome to reach us if you have any questions regarding juice pouches. Have a nice day.