Flat bottom pouches have become an increasingly popular choice in the premium food and coffee packaging market. This pouch style blends the best features of stand-up and box pouches, delivering exceptional shelf appeal and strong functional performance. The flat, reinforced base allows the pouch to stand upright and securely on retail shelves, while the side gussets and wide top opening provide greater capacity and make filling more efficient.

Made with high-barrier laminated films, flat bottom bags offer excellent protection against oxygen, moisture, and light—ensuring product freshness throughout filling, transportation, and storage. Their robust structure also supports heavier contents without collapsing or losing shape.

Visually, flat bottom pouches offer outstanding branding opportunities. With five fully printable panels—front, back, two sides, and bottom-brands have ample space for creative artwork, storytelling, and detailed product information. As shown in the example above, transparent windows on both side gussets further enhance presentation by allowing customers to see the product inside, increasing trust and shelf impact.

Available in compostable, recyclable, or traditional material structures, flat bottom pouches are a versatile and premium solution for brands seeking durability, aesthetics, and eco-friendly performance in their packaging.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

In this post, we will take a closer look at the exact film structure used in the 250 g Chinese Hetian dates box-bottom bags. We hope this analysis can serve as a useful reference for your own packaging development.

Packaging Foil Materials

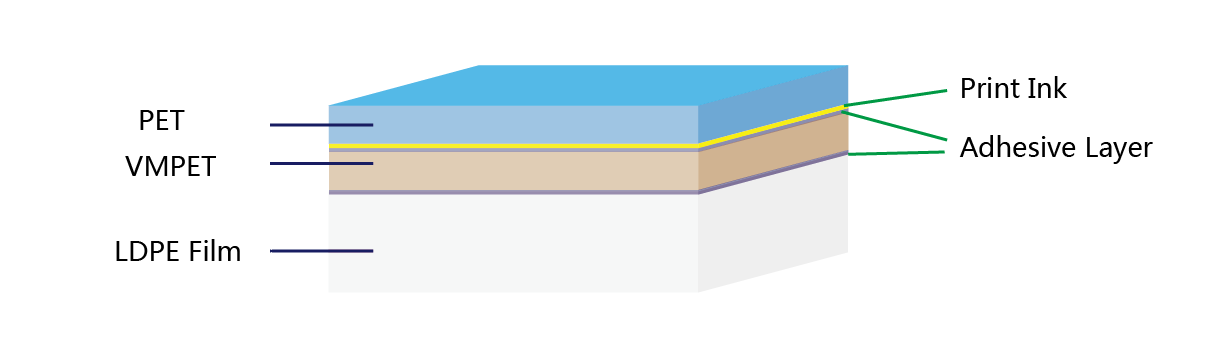

The figure below shows the composition structure of this laminated foil material used to convert this flat bottom Chinese He Tian dates bag.

It is made of three layers, with the outside PET film 12 microns working as the print substrate film, the VMPET film 12 microns working as the middle barrier layer, and finally, the LDPE film working as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of 250g Chinese dates.

Ok,let’s get into a deeper understanding of each substrate film material.

PET Film

PET film, or polyethylene terephthalate film, is a thermoplastic polymer resin that is a type of plastic film. It is a versatile material with many uses due to its physical, mechanical, optical, thermal, electrical, and chemical properties. PET film is available in various thicknesses, widths, and transparencies.

PET film has many uses, including:

- Packaging: PET film is used in containers for food and liquids, as well as in flexible packaging.

- Manufacturing: PET film is used in thermoforming.

- Engineering: PET film is combined with glass fiber to create engineering resins.(树脂)

- Films: PET film is used for antimicrobial(抗菌)and insulation(绝缘) films, surface protection, hard-coats films, protective films, and printable films.

- Labels: PET film is used for labeling and label face-stocks.

- Security: PET film is used for security and tamper evident films.防伪 防篡改

- Display signs: PET film can be used to make outdoor display signs for advertising.

- ID cards: PET film can be used to print business ID cards.

VMPET Film

Vacuum metallizing, also known as vacuum metallization, is a manufacturing process that coats a metal onto a non-metallic substrate in a vacuum chamber through evaporation. It’s a type of physical vapor deposition (PVD) Vacuum metallizing can be used for both decorative and functional purposes:

Vacuum metallizing can create reflective and shielding coatings. Reflective coatings, often made from aluminum, can be up to 90% reflective. Shielding coatings can be made from metals with high electrical conductivity, like copper or aluminum, to protect against electronic interference. Vacuum metallizing can also create vapor barriers and heat shielding.

LDPE

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance.

LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. However, the FDA does not consider recycled LDPE to be safe for food usage. You can recognize LDPE on products by the number four in a triangle, usually on the bottom or side of the item.

LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. It’s also lightweight, corrosion resistant, and has good chemical and impact resistance. LDPE is often used in packaging materials, such as milk pouches and food wrappers, because it’s a good moisture barrier and keeps products fresh. It’s also used in orthotics and prosthetics.

These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/VMPET12/LDPE foil.

Great Standup Effect

This structure enables the pouch to stand upright even when unfilled and maintain stable standing after filling—boasting strong stability on shelves and resistance to tipping. Meanwhile, PET offers good stiffness, VMPET enhances barrier properties and gloss, and LDPE provides excellent heat-salability and flexibility. The composite of these three materials ensures the pouch’s standing performance while delivering comprehensive overall functionality.

Advantages of the Transparent Window

Enhanced Shelf Appeal

The side transparent window creates a premium, modern look without interrupting the main front-panel design. It lets customers visually inspect the product while preserving the clean branding space on the front.

Better Use of Branding Space

Because the window is on the side, the entire front and back panels remain fully available for high-impact artwork, storytelling, sustainability messages, or product information.

Excellent Airtight Property for Zipper lock

It bonds securely with the pouch’s inner LDPE film, ensuring excellent airtight performance. This allows the package to be opened and closed repeatedly while keeping the platinum chips fresh for an extended period after opening.

We conduct strict quality-control procedures to verify the zipper’s airtightness. For a clearer understanding of the testing process, please feel free to refer to the video below.

Mechanical Property

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order based on customer requirements.

Drop Test

In our daily QC process, we use a more reliable method to evaluate whether the bag strength meets the final requirements of different customers. For each order, we conduct a drop test, and the drop-test standard is adjusted according to the specific needs and performance criteria of each customer.

Here, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/VMPET/LDPE foil laminate will be able to meet most of the requirements for platinum chips. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 1.25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.36 |

More Sustainable Materials Options

With the increasing environmental burden caused by fossil-based polymer waste, the demand for sustainable packaging continues to rise. Recent studies in the detergent market indicate that consumers are becoming more willing to purchase products that clearly demonstrate a commitment to environmental responsibility.

Compostable Packaging Materials

This kraft paper PLA+PBAT film pouch was burid into soil on Nov 26, 2021, and one and half years passed, dated on August 17, 2023, we are going to check the degradation process of this compostable foil pouch. Actually, all the outside layer kraft paper degraded into inorganic elements without any things left. However, the inner PLA+PBAT film did not degrade into nutrients. Surely, the activity of micro-organism is keeping a lower level for soil conditions and surely it will need a longer time to degrade. We got it well buried again, and surely, we will keep you posted with the progress of this composting test.

We have developed several compostable foil materials that can be intended for roasted sunflower seeds, with the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the higher cost of compostable foil materials, fully recyclable sachets and roll films are quickly becoming the preferred choice in the market due to their cost-effectiveness and suitability for lightweight packaging.

Thanks to ongoing advancements in PE film barrier technology, recyclable foil-free laminates can now provide reliable protection for products such as sunflower seeds by effectively blocking moisture. For applications requiring even stronger performance, a PVA coating can be applied to LDPE or HDPE films to further improve moisture resistance. In addition, integrating an EVOH barrier layer into biaxially oriented PE (BOPE) films significantly enhances oxygen barrier properties, making this structure an excellent solution for modern flexible packaging.

If you have any questions or would like to learn more about our juice pouch packaging solutions, please feel free to reach out.

Have a great day!