Flat bottom pouches have gained recognition among premium food and coffee brands for their clean appearance and reliable performance on the shelf. Their box like base gives the package a firm, stable stance, while the expanded side panels create generous internal space and support smooth, efficient filling during production.

Why Flat Bottom Pouches Stand Out

- Strong Shelf Presence

The box like bottom allows the pouch to stand firmly on display.

Wide side panels create more internal capacity and improve filling efficiency.- Reliable Product Protection

Made with high barrier laminated films that block oxygen and moisture.

Helps maintain aroma, texture, and overall freshness during storage and transport.

The structure remains stable even when holding heavier products.

- Reliable Product Protection

- Expanded Branding Space

Five separate printable areas: front, back, two sides, and bottom.

Ideal for artwork, product information, and brand storytelling.

Optional transparent sections on side panels let customers view the product directly. - Flexible Material Choices

Available in compostable structures, recyclable materials, and traditional laminations.

Suitable for brands with different sustainability requirements. - Professional Manufacturing Support

Our facility in Qingdao focuses on flexible packaging solutions.

We collaborate with advanced film suppliers to provide diverse and dependable material options.

Based in Qingdao, our facility specializes in flexible packaging and works closely with leading film suppliers to ensure we deliver diverse and reliable material solutions for our clients.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

In this post, we will share the exact film structure used for the 500 g Chinese dates flat bottom bag. We hope this information supports anyone developing similar packaging and provides a useful reference for future projects.

Packaging Foil Materials

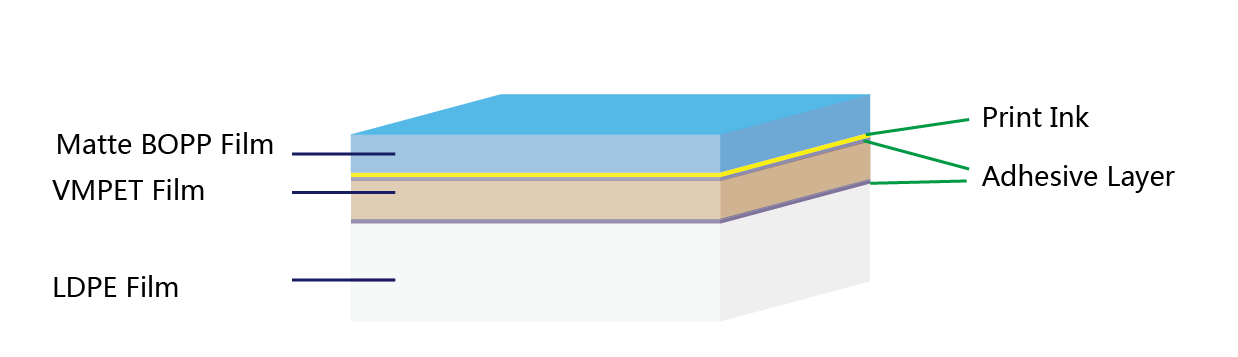

The figure below shows the composition structure of this laminated foil material used to convert this flat bottom Chinese dates bag.

It is made of three layers, with the outside being the print substrate film Matte BOPP film 18 microns working as the print substrate film, the VMPET film 12 microns working as the middle barrier layer, and finally, the LDPE film working as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of 500g Chinese dates.

MatteBOPP Film

Matte BOPP, or matte biaxially oriented polypropylene, is a polymer film designed with a soft, non reflective surface that diffuses light rather than bouncing it back. With its subtle matte appearance, this film is often chosen to enhance visual appeal and give packaging a modern, refined look.

The material is typically structured with multiple layers, including a polypropylene core, tie layers, and a skin copolymer layer applied on one or both sides. It is produced through extrusion followed by biaxial stretching, and can be manufactured using either the tubular process or the tenter frame method.

VMPET Film

VMPET film refers to vacuum metallized polyester film. It is produced by depositing a very thin layer of aluminum onto a PET substrate under vacuum conditions, forming a bright metallic surface that is widely used in flexible packaging and stand up pouches.

Vacuum metallizing serves both decorative and functional purposes. It can create highly reflective coatings made with aluminum, reaching reflectivity levels of up to ninety percent. It can also form shielding layers using metals with strong electrical conductivity, such as aluminum or copper, which help block electronic interference. In addition, vacuum metallizing can provide vapor barrier performance and heat shielding.

This technology is commonly applied to device components, plastic parts, and exterior parts of various products. It offers multiple advantages, including an improved appearance, added surface protection, resistance to oxygen and moisture, and the ability to either create or limit electrical conductivity as required.

LDPE Film

LDPE is both recyclable and reusable, which makes it a common choice for environmentally conscious applications. However, recycled LDPE is not approved by the FDA for direct food contact. Products made from this material can be identified by the number four inside a recycling triangle, usually found on the bottom or side of the item.

LDPE is a clean and stable material with strong resistance to breaking. It is light in weight, corrosion resistant, and provides reliable performance against chemicals and impact. Because it offers a good moisture barrier and helps maintain product freshness, it is widely used in packaging such as milk bags and food wrappers. Beyond packaging, LDPE is also utilized in the production of orthotic and prosthetic components.

Great Standup Effect

This pouch is built from a coordinated set of materials that includes matte BOPP, kraft paper, metallized PET, and LDPE. Each layer plays a distinct role in shaping both the appearance and performance of the final package. The matte BOPP layer gives the surface a smooth and contemporary character. Metallized PET contributes advanced barrier protection by reducing the impact of oxygen, moisture, and light. LDPE forms the inner sealing layer, offering flexibility and strong heat seal performance.

Because these materials are combined in a balanced way, the pouch can stand firmly on its base and hold its shape through filling, storage, and display. The paper layer adds structural support, the metallized PET enhances protective capability, and the LDPE interior maintains a secure seal that helps preserve product freshness. The overall result is a packaging structure that brings together a polished look with dependable strength for a wide variety of products.

Advantages of the Transparent Window:

- Improved Product Visibility: A side window allows customers to view the product directly while keeping the main front panel clean and focused. This combination highlights both the natural texture of kraft paper and the actual product, creating an inviting and trustworthy presentation.

- Maximized Branding Opportunities: By placing the window on the side, the front and back panels remain fully available for design elements, such as brand logos, storytelling, product information, or sustainability messages. This ensures the package stands out on the shelf while giving shoppers a clear look at the contents.

Excellent Airtight Property for Zipper lock

The zipper adheres securely to the pouch’s inner LDPE layer, providing reliable airtight sealing. This allows the package to be opened and closed repeatedly while maintaining the freshness of the product long after the first use.

We implement a rigorous quality control process to ensure the zipper’s sealing performance meets our standards. For a better understanding of the testing procedure, a demonstration video is available for reference.

Mechanical Property

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order based on customer requirements.

Drop Test

During our daily quality control process, we use a dependable method to assess whether the strength of each bag meets the final expectations of different customers. Every order includes a drop test, and the testing standard is adjusted based on the customer’s specific requirements and the performance level they expect.

In this case, the drop test is carried out from a height of one point six meters. The bag is dropped three times, and we then check carefully to confirm that it has not broken.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, MatteBOPP/VMPET/LDPE foil laminate will be able to meet most of the requirements for platinum chips. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 1.25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.36 |

More Sustainable Materials Options

With the increasing environmental burden caused by fossil-based polymer waste, the demand for sustainable packaging continues to rise. Recent studies in the detergent market indicate that consumers are becoming more willing to purchase products that clearly demonstrate a commitment to environmental responsibility.

Compostable Packaging Materials

This kraft paper PLA+PBAT film pouch was burid into soil on Nov 26, 2021, and one and half years passed, dated on August 17, 2023, we are going to check the degradation process of this compostable foil pouch. Actually, all the outside layer kraft paper degraded into inorganic elements without any things left. However, the inner PLA+PBAT film did not degrade into nutrients. Surely, the activity of micro-organism is keeping a lower level for soil conditions and surely it will need a longer time to degrade. We got it well buried again, and surely, we will keep you posted with the progress of this composting test.

We have developed several compostable foil materials that can be intended for roasted sunflower seeds, with the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the higher cost of compostable foil materials, fully recyclable sachets and roll films are quickly becoming the preferred choice in the market due to their cost-effectiveness and suitability for lightweight packaging.

Thanks to ongoing advancements in PE film barrier technology, recyclable foil-free laminates can now provide reliable protection for products such as sunflower seeds by effectively blocking moisture. For applications requiring even stronger performance, a PVA coating can be applied to LDPE or HDPE films to further improve moisture resistance. In addition, integrating an EVOH barrier layer into biaxially oriented PE (BOPE) films significantly enhances oxygen barrier properties, making this structure an excellent solution for modern flexible packaging.

If you have any questions or would like to learn more about our juice pouch packaging solutions, please feel free to reach out.

Have a great day!