It is always very important to get a perfect package for your roasted bean products, as coffee packaging is always an effective extension of your coffee shop, so that you can communicate your branding to consumers who do not have the opportunity to visit your cafe.

Amazing packaging design undoubtedly helps you improve brand awareness and make your products stand out from the crowd, which in turn helps attract new customers.

Of course, the film materials matters much to decide the final print effect and profile for your package. Take this 1kg bottom coffee bag for example, the unusual design is finalized onto the quality film materials, and finally create an fanstatic package branding, which helps catch your customer’s eyes and tell a compelling brand story, all while keeping your coffee in original freshness for a longer time.

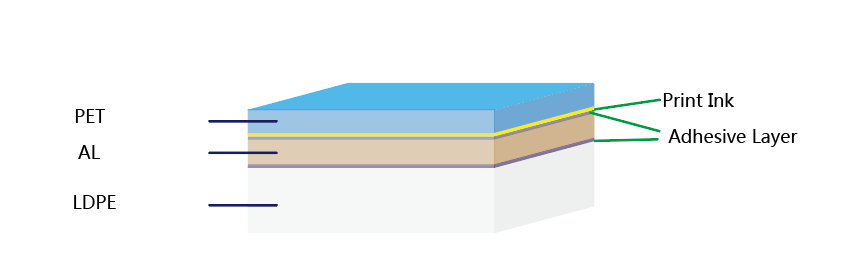

Foil Laminate Structure

- PET12, is one of the most common used printing substrates in flexible packaging pouches. With great clarity, stable mechanical strength and excellent printability, it is able to present the customer artwork print in great quality.

- Al7, is short for aluminum foil metal sheet with thickness 7 microns, which is the most common used thickness in flexible packaging. It is of the best barrier performance among all the film materials, which can keep the orginal flavor and fragance for a prolonged time.

- LDPE, means low density polyethylene film, which is the most used inner sealing layer for the coffee bag. It is able to provide enough sealing strength and airtight property for the final packages.

PET film

PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing

AL film

AL Film, short for Aluminum Foil, is one of the most important barrier materials used in flexible packaging. It provides an excellent barrier performance against oxygen, moisture, light, and odors, which helps extend the shelf life of sensitive products such as food, coffee, snacks, pharmaceuticals, and chemicals.

Aluminum foil has a stable structure, is highly puncture-resistant, and maintains its barrier properties even in thin gauges. It also offers strong heat resistance, light-blocking capability, and printability when laminated with other films such as PET, BOPP, or PE.

Because of its outstanding preservation ability and high-quality appearance, AL-laminated packaging is widely used in premium-grade flexible packaging.

LDPE film

LDPE (Low Density Polyethylene) is a soft, flexible, and highly versatile packaging material widely used in the flexible packaging industry. It is known for its excellent sealing performance, good impact resistance, and high flexibility, making it ideal as an inner-layer film in laminated structures.

LDPE provides good moisture resistance, transparency, and smoothness, allowing products to be filled easily while maintaining strong and reliable heat seals. It is commonly used in food packaging, frozen products, detergents, agricultural supplies, and various consumer goods.

In laminated packaging, LDPE is often combined with other materials such as PET, BOPP, or AL to enhance durability, barrier performance, and product shelf life. Typical structures include PET/LDPE, PET/AL/LDPE, and BOPP/LDPE.

Because of its cost-effectiveness, safety, and excellent sealing properties, LDPE remains one of the most widely used materials for pouch-making and film packaging.

Great Standup Effect

You can check the quality of bag through this video.

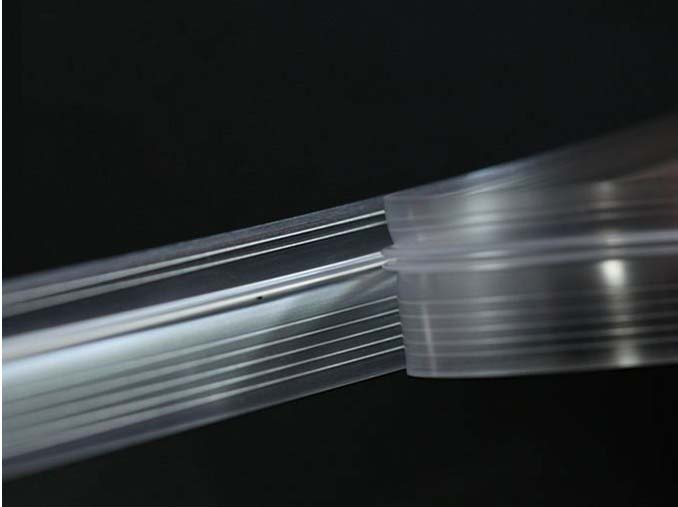

Excellent Airtight Property for Zipperlock

The inner zipper provides an additional sealing layer inside the bag, creating double protection for the product. It helps improve airtightness, maintain freshness, and reduce the risk of leakage or contamination during transportation and storage. This feature is especially suitable for food products such as coffee, nuts, and powder items, and it also enhances the overall premium feel and user experience of the packaging.

Mechanical Properties

The PET/AL/LDPE laminate offers excellent overall mechanical performance due to the synergy of each layer:

Excellent Puncture and Tear Resistance

The aluminum foil (AL) layer significantly improves puncture and tear resistance, providing reliable protection for products with sharp edges or irregular shapes.

Outstanding Flexibility and Heat Seal Performance

The LDPE layer offers excellent flexibility and softness, along with strong and consistent heat-sealing properties, ensuring tight seals and effective leak prevention under stress.

Balanced Barrier Performance and Mechanical Strength

The PET/AL/LDPE structure delivers an optimal balance of rigidity, flexibility, and barrier performance, maintaining package integrity during bending, handling, and daily use.

Reliable Performance During Filling and Transportation

This laminate structure ensures stable performance at different filling speeds and maintains durability throughout storage, transportation, and distribution.

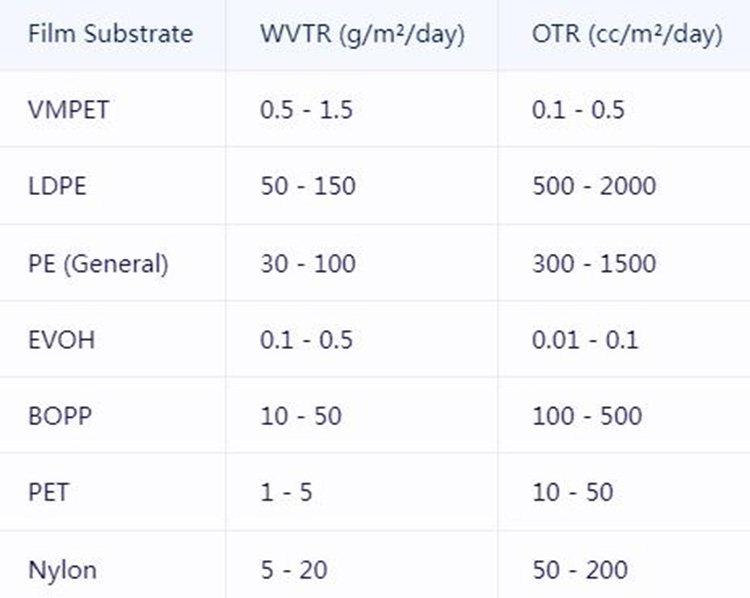

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

More Sustainable Materials Options

With the increasing environmental burden caused by fossil-based polymer waste, the demand for sustainable packaging continues to rise. Recent studies in the detergent market indicate that consumers are becoming more willing to purchase products that clearly demonstrate a commitment to environmental responsibility.

Compostable Packaging Materials

This kraft paper PLA+PBAT film pouch was burid into soil on Nov 26, 2021, and one and half years passed, dated on August 17, 2023, we are going to check the degradation process of this compostable foil pouch. Actually, all the outside layer kraft paper degraded into inorganic elements without any things left. However, the inner PLA+PBAT film did not degrade into nutrients. Surely, the activity of micro-organism is keeping a lower level for soil conditions and surely it will need a longer time to degrade. We got it well buried again, and surely, we will keep you posted with the progress of this composting test.

We have developed several compostable foil materials that can be intended for roasted sunflower seeds, with the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the higher cost of compostable foil materials, fully recyclable sachets and roll films are quickly becoming the preferred choice in the market due to their cost-effectiveness and suitability for lightweight packaging.

Thanks to ongoing advancements in PE film barrier technology, recyclable foil-free laminates can now provide reliable protection for products such as sunflower seeds by effectively blocking moisture. For applications requiring even stronger performance, a PVA coating can be applied to LDPE or HDPE films to further improve moisture resistance. In addition, integrating an EVOH barrier layer into biaxially oriented PE (BOPE) films significantly enhances oxygen barrier properties, making this structure an excellent solution for modern flexible packaging.

If you have any questions or would like to learn more about our juice pouch packaging solutions, please feel free to reach out.

Have a great day!