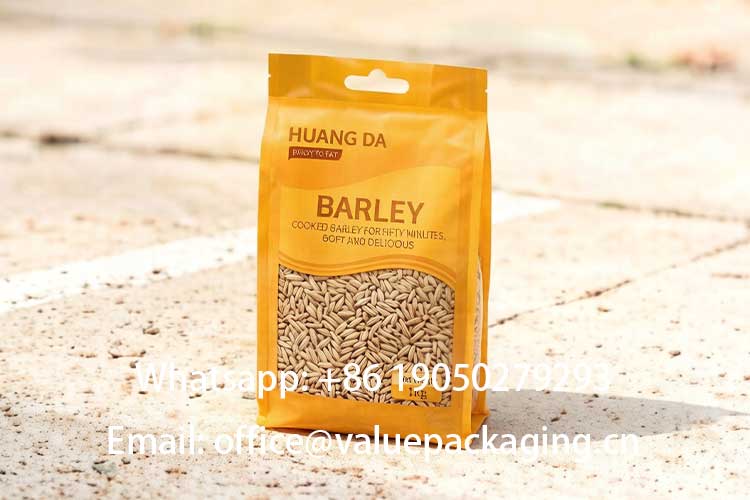

In the flexible packaging industry, a range of performance tests are widely used to assess overall pouch quality and durability, such as seal strength testing, moisture barrier performance, and compression resistance testing. Before these evaluations can provide meaningful and accurate results, flexible packaging must first demonstrate sufficient impact resistance during real-world handling, storage, and transportation. For barley packaging applications, particularly four-side seal pouches, drop testing plays a critical role in verifying packaging integrity and structural reliability.

Barley products are typically packed in relatively heavy weights, which places constant mechanical stress on packaging throughout filling, stacking, warehousing, and logistics operations. During transportation and distribution, cartons may be dropped, pallets shifted, and individual pouches subjected to sudden impact forces. If a four-side seal pouch lacks adequate impact strength, common failures such as seal breakage, corner cracking, or film tearing can occur. These issues not only result in product loss but also compromise barley quality, shelf life, and brand credibility.

1.Understanding Impact Resistance in Four-Side Seal Barley Packaging

Compared with stand-up pouches, four-side seal bags rely entirely on seal strength and film structure for load support. This makes impact resistance particularly important.

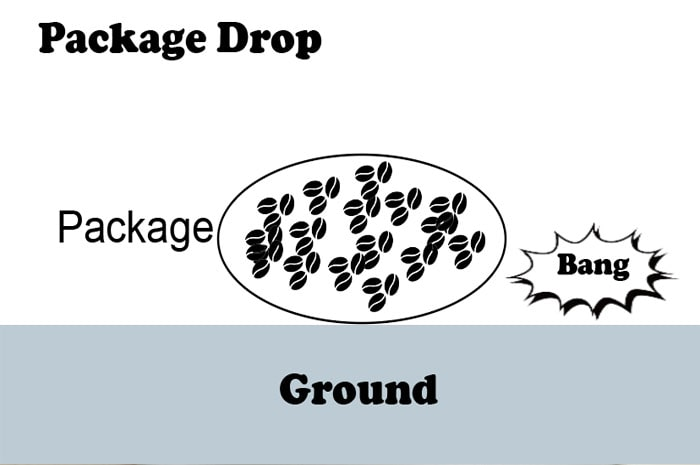

Seal Stress Along All Four Edges

When a filled four-side seal pouch is dropped, the internal barley mass shifts rapidly, transferring force directly to the perimeter seals. Any inconsistency in seal width, temperature, or pressure can become a weak point under impact, especially at seal intersections and corners.

Corner Impact Sensitivity

Corner areas in four-side seal packaging are exposed to concentrated stress during drops. Repeated corner impacts may cause seal fatigue or microcracks that weaken package integrity over time.

Film Rigidity and Flexibility Balance

Barley packaging films must maintain sufficient rigidity to support product weight while remaining flexible enough to absorb impact. Films that are too stiff may crack, while overly soft structures may stretch and weaken seal areas during drops.

2.Applying Drop Testing to Four-Side Seal Barley Pouches

Drop testing for barley packaging is designed to replicate real-world logistics conditions rather than ideal laboratory environments. Test samples are randomly selected from standard production batches and filled with actual barley or equivalent weight materials to reflect real internal load and movement.

Typical test conditions include:

Drops from heights that simulate manual handling, pallet transfer, and warehouse operations

Multiple drop orientations, including flat drops, edge impacts, and corner impacts

Repeated drops to evaluate cumulative stress on seals and film structure

These tests help reveal how four-side seal pouches perform under realistic impact scenarios and where structural improvements may be required.

3.Our Drop Testing Methodology

Sample Selection

Four side seal pouches are randomly taken from routine production runs to ensure test results accurately reflect actual manufacturing consistency.

Drop Height Definition

Standard retail-size barley packs are tested at drop heights representing packing line handling and shelf replenishment. Larger or heavier packs are tested at increased heights to simulate pallet movement and warehouse handling.

Orientation and Repetition

Each pouch undergoes multiple drops in different orientations, with particular focus on seal edges and corners, which are critical stress zones in four-side seal structures.

Post-Test Inspection

After testing, pouches are examined for seal splitting, corner damage, pinholes, film cracking, and structural deformation. Only packaging that remains fully sealed and functional is considered to meet performance requirements.

4.Drop Testing Is Not Optional in Barley Packaging

Drop testing verifies whether four-side seal packaging can physically protect barley products throughout the supply chain.

Seal Failure Risk

Impact-related seal damage can lead to gradual leakage or sudden rupture, especially under high product weight.

Moisture Ingress

Even minor seal defects caused by impact may allow moisture penetration, affecting barley quality during storage.

Handling and Distribution Stability

Packaging failure during transportation increases operational risk, repacking costs, and customer complaints.

By confirming impact resistance at the earliest stage, further evaluations of barrier performance and shelf life are based on structurally sound packaging.

5.What Reliable Packaging Actually Delivers to Barley Brands

The primary purpose of drop testing is to ensure that packaging distributes impact forces evenly across all four seals instead of concentrating stress at specific points.

Well-designed four-side seal packaging maintains seal integrity after repeated impacts, supports stable product containment, and preserves a clean appearance throughout distribution. Reliable packaging reduces product loss, improves handling efficiency, and strengthens brand confidence at both retail and bulk distribution levels.

6.Building Impact Reliability Into Barley Packaging Quality Control

Drop testing is integrated into routine quality control processes for barley packaging. By applying standardized drop conditions across production batches, seal strength consistency and structural reliability can be verified over time.

Evaluations after repeated drops ensure that every four-side seal pouch meets the same requirements for durability, moisture protection, and functional performance.

7.Conclusion

Drop testing exposes the hidden weak points that standard inspections may miss. For four-side seal barley packaging, it confirms whether the pouch can endure cumulative impact, maintain seal integrity, and protect product quality from filling through final delivery.

By validating impact resistance first, barley packaging performance is assessed where it matters most: under real handling conditions, not controlled assumptions.