Cleaning chemicals are widely used in households, and their packaging comes in many forms. Among the most common are bottles and pouches. Compared with bottles, pouches save storage space, reduce costs, and allow for attractive printing of brand logos and designs, while still meeting the needs of most consumers.

Stand-up pouches, in particular, offer excellent shelf display appeal. Their gusseted bottoms provide extra capacity and stability. To ensure products are well protected throughout filling, transportation, and distribution, it is essential that the packaging materials are durable and reliable.

In order to maximize antioxidant efficacy and maintain stability, spout pouches for natural antioxidants are commonly made with a PET/BOPA/LDPE film structure.

For large-capacity products, PA is an excellent choice as it enhances rigidity and ensures a better standing effect. This not only improves the pouch’s overall stability but also gives it a more premium appearance. In addition, creative artwork can be printed on all sides of the stand-up pouch, allowing ample space to display branding elements and product information. This maximizes shelf appeal and makes the final package more attractive to consumers.

As a well-established flexible packaging converter in Qingdao, China, we specialize in maximizing the value of today’s advanced packaging film materials, as listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We specialize in designing story-driven stand-up bags for cleaning chemicals that not only boost product sales but also strengthen brand image.

In this post, we’ll break down the specific foil materials used in a 3000ml stand-up pouch for cleaning chemicals, providing a useful reference for your packaging needs.

Packaging Foil Materials

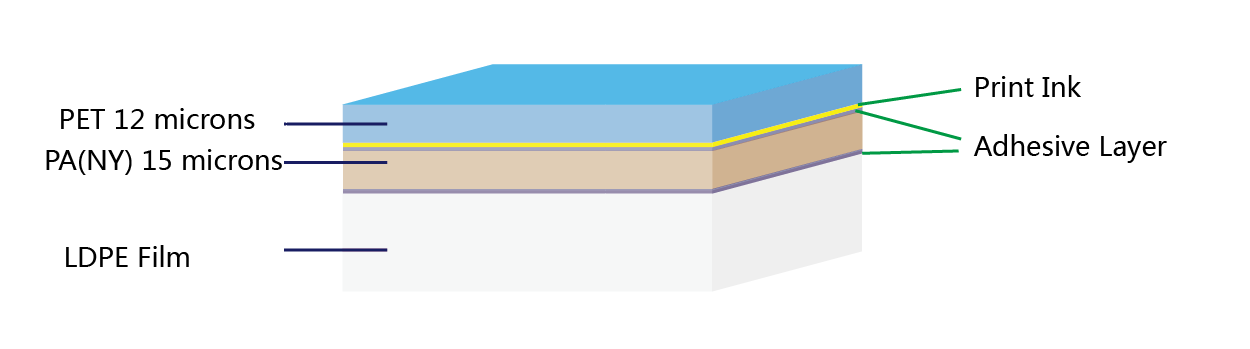

This foil material features a reinforced structure with excellent barrier and mechanical properties, making it highly suitable for liquid cleaning chemical packaging. The structure is PET/BOPA/LDPE, and the graphic design is shown below.

The packaging structure adopts a triplex laminate design: a 12 µm PET film as the outer layer serving as the print carrier and providing surface protection, a 15 µm BOPA film as the middle layer to enhance mechanical strength and barrier performance, and an LDPE film as the inner sealing layer ensuring chemical resistance and heat-sealability. The thickness of the LDPE layer will be customized and reinforced to meet the functional and safety requirements for containing 3000 ml cleaning chemicals.

Next, let’s get a deeper understanding of each substrate film material.

PET Film

PET film, or polyethylene terephthalate film, is a thermoplastic polymer resin that is a type of plastic film. It is a versatile material with many uses due to its physical, mechanical, optical, thermal, electrical, and chemical properties. PET film is available in various thicknesses, widths, and transparencies.

BOPA Film

BOPA, or Biaxially Oriented Polyamide (also known as biaxially oriented nylon, NY), is a versatile and flexible film material. It is produced by biaxially stretching polyamide resins through processes such as flat cast die extrusion, three-layer co-extrusion, and two-step tenter frame orientation.

BOPA film has many properties that make it useful for various applications, including packaging, consumer goods, and industrial uses:

- Barrier properties: BOPA film can act as a barrier against moisture and oxygen. It can also be used to package greasy or aggressive substances.

- Mechanical strength: BOPA film is flexible, has high tensile strength, and is resistant to impact and punctures.

- Other properties: BOPA film is also transparent, glossy, and can be printed on.

BOPA film is especially popular for food packaging because it can help keep food fresh and can display important information like whether the product is organic, vegetarian, or halal, and if it contains allergens. The growing demand for packaged food and the pharmaceutical industry is expected to drive the growth of the BOPA film market in the coming years.

LDPE Film

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. It is often used for manufacturing plastic goods like cling wrap, juice containers, orthotics, and prosthetics.

LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. It’s also lightweight, corrosion resistant, and has good chemical and impact resistance. LDPE is often used in packaging materials, such as milk pouches and food wrappers, because it’s a good moisture barrier and keeps products fresh. It’s also used in orthotics and prosthetics.

LDPE is environmentally friendly, low-cost, and low-energy. However, it’s not suited for applications that require stiffness, high temperature resistance, or structural strength. LDPE also has limited resistance to some chemicals, such as aliphatic and aromatic hydrocarbons, mineral oils, and oxidizing agents.

The customer artwork is printed reversely on the inner side of the first PET film layer in the gravure printing system. These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET/BOPA/LDPE foil.

Barrier Performance

The barrier performance of multi-material laminates is typically evaluated using WVTR (Water Vapor Transmission Rate) and OTR (Oxygen Transmission Rate). The table below presents typical WVTR and OTR values for the most commonly used substrate films in flexible packaging.

Based on experience, partial packages of liquid cleaning chemicals should be light-resistant to ensure the formula performs as intended. The primary reason is to prevent light from accelerating oxidation, which can compromise the product’s effectiveness. Therefore, it is essential to store liquid cleaning chemicals in a dark environment, away from direct light, to effectively extend their shelf life.

You can easily find out the typical values of moisture vapor transmission rate and oxygen transmission rate of this multilayer foil PET12/BOPA15/LDPE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 19.5 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 8.5 |

So, some reinforced foil structures are better protections for the freshness and flavors, with some available items listed below.

- PA/VMPET/LDPE

- BOPP/BOPA/LDPE

You may reach us for further ideas on each foil structure if you need any assistance

Technical Data Sheet of 3000ml cleaning chemicals spout doy-pack

Here, we attach the specification sheet of this 3000ml cleaning chemicals spout pouch based on foil laminate PET/BOPA/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

More Sustainable Materials Options

With the growing burden of fossil-based polymer materials being discarded into the environment, the demand for sustainable packaging has reached unprecedented levels, driving businesses toward more eco-friendly practices. Recent studies of the juice market show that consumers are increasingly inclined to purchase products that demonstrate a commitment to environmental sustainability.

Compostable Packaging Materials

Compostable packaging is made from plant-based fibers such as cellulose, or bio-based resources like corn starch, cassava, and sugarcane. The resins derived from these materials are commonly referred to as biopolymers, which can naturally decompose into inorganic elements through the action of algae, bacteria, and other microorganisms.

By adopting compostable packaging, brands demonstrate their commitment to sustainability while satisfying growing consumer demand for environmentally responsible products. It’s a practical step toward a greener future without compromising product quality or aesthetics.

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Ok, let’s end here, you may reach us if you have any questions, nice day.