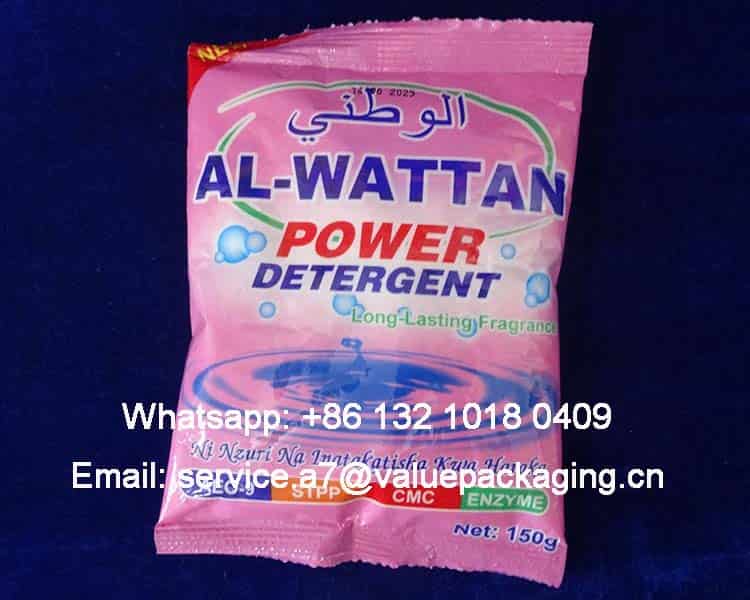

The Pillow Pouch is very suitable for packaging laundry detergent powder. This type of bag can achieve high-speed automated packaging, improve production efficiency and reduce unit packaging costs. The bag is light and easy to transport and display.

Aluminum foil combined with a variety of flexible polymer film materials provides excellent barrier properties to protect detergent powder from air and moisture. In addition, both sides of the pillow bag can be printed with creative patterns, including brand and sales information, making the packaging more attractive.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, which are listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- Vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- Biodegradable film materials

- Compostable substrate films

- Fully recyclable substrate films

In this article, we will analyze the specific aluminum foil material of this 150g laundry detergent powder packaging bag, hoping to provide a reference for your product.

Ok, let’s get into the details of this detergent powder pillow pouch.

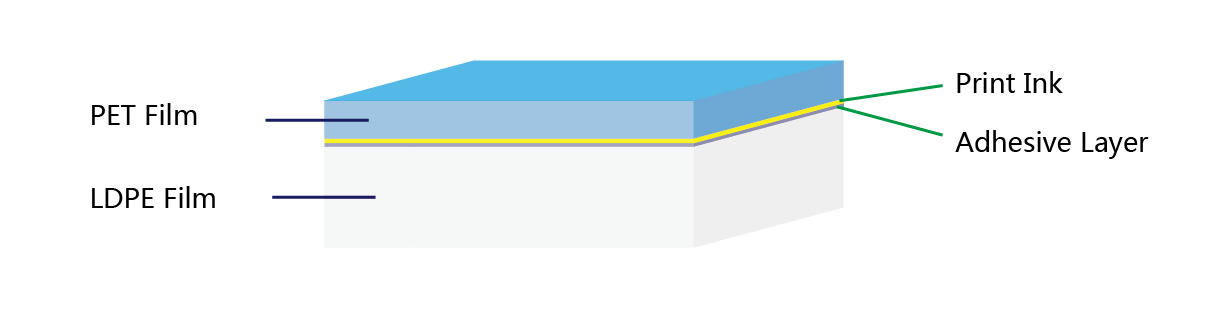

Packaging Foil Materials

The figure below shows the composition structure of the laminated foil material used to convert this pillow pouch laundry detergent bag. The multi-layer structure usually consists of a printing layer and a heat-sealing layer to ensure that the packaging has good mechanical strength, sealing and moisture-proof properties.

It consists of two layers, the printing layer is formed by 12 micron PET film, and the heat sealing layer is formed by LDPE film. The thickness of LDPE film can be adjusted according to the requirements of 150g washing powder.

Next, we will introduce each specific layer to give you a deeper understanding of this structure.

PET Film

PET film is an excellent plastic film that is widely used in flexible packaging structures, especially as an outer layer material. It has high strength, good heat resistance, excellent printability and excellent transparency. These properties make it perfect for displaying customers’ artwork while providing strong mechanical strength to the final package.

In the flexible packaging industry, the most commonly used thickness for PET film is 12 microns, which is equivalent to 0.48 gauge. Therefore, whenever you see references to PET12 or 0.48 g PET, you can understand that they refer to the same material.

LDPE film

LDPE (Low-density polyethylene) is a soft, transparent, tough thermoplastic material that is widely used in flexible packaging structures and is particularly suitable as an inner heat-sealing material. It has excellent heat-sealing properties and can seal quickly even at low temperatures, ensuring that the packaging is firm and leak-free. It is particularly suitable for the packaging of powdered and granular products, such as laundry detergent, coffee powder, desiccant, etc.

LDPE film is highly soft and can effectively fit the shape of the contents, reducing the risk of bag breakage caused by extrusion. At the same time, its good moisture-proof properties can effectively block water vapor and extend the shelf life of the product. The material itself has good chemical stability and can resist erosion by a variety of chemical components, making it suitable for washing products containing active substances.

These 2 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/LDPE foil.

Thickness

In the picture below, we can see that the overall thickness of this pouch is 0.184 mm, which means the thickness of this foil laminate should be 0.092mm.

As an outer layer material, PET provides high strength, high transparency and excellent printing performance, and its thickness is usually 12μm.

As an intermediate barrier layer, VMPT only needs 12μm in thickness, which can provide excellent oxygen and water vapor barrier performance and enhance the gloss and decoration of packaging.

As a heat sealing layer, LDPE usually has a thickness of 40-100μm, which provides good heat sealing, flexibility and puncture resistance.

Wonderful Printing Effect

In order to achieve good printing effects, the outer material of the packaging needs to have stable surface tension, strong adhesion, high temperature resistance and not easy to deform.

The surface of PET film is flat and smooth, and has excellent printing adaptability. After corona treatment, its surface tension is stable, and it can firmly absorb ink, ensuring that the pattern is bright in color, clear in layers, and not easy to fall off.

Mechanical Properties

We put mechanical performance first in factory manufacturing. Our quality control system takes strict measures to ensure that every order can achieve the expected results.

The following video is the tensile strength and elongation test of PET+LDPE of the same thickness, 90 microns.

Put 500g of detergent powder in a bag with a thickness of 80 microns and perform a drop test from a height for a total of 5 times to check whether it will break.

Barrier Performance

Generally, the essential formulas of a household laundry detergent powder should include, but not be limited to, the list below.

- Surfactants

- Sodium Carbonate

- Phosphates / Zeolites

- Sodium Silicate

- Optical Brighteners

- Enzymes (Protease, Lipase)

- Fragrance

- Anti-redeposition Agents

Based on the above, it should be stored in a well-sealed package to avoid moisture that affects solubility and cleaning power. Avoid direct sunlight that may cause degradation of enzymes, brighteners and other ingredients in the detergent.

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil to decide if this spout doy-pack is finally meeting the requirements of each customer.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 9.84 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 36.2 |

Technical Data Sheet of 150g laundry detergent powder pouch

Here, we attach the specification sheet of this 150g laundry detergent liquid sachet based on foil laminate PET/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (MPa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to further understand this PET/PA/LDPE laminated foil, you may just read it here.

Now it’s the end. You are welcome to reach us if you have any questions regarding detergent powder pouches. Have a nice day.