Metallized foil laminate is intended for describing the multilayer foil laminate with metallized film trapped between, with VMPET film the most applied in the mutilayer laminate. In this post, please allow us to get deeper into this topic.

Multi-layer foil laminate

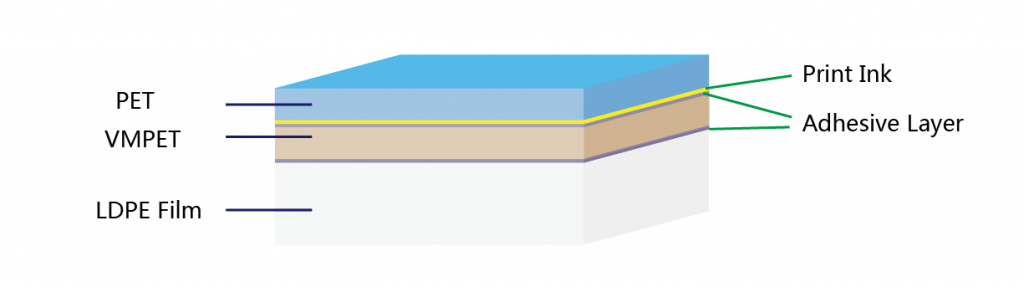

Below graphic shows the typical foil structure when it is intended to function as a barrier package with custom print.

- Outer PET film works as print substrate film

- VMPET film layer, works as middle bone layer and barrier layer

- Inner LDPE film works as inner sealing layer and going to achieve different types and packages.

This foil structure should be considered as the most economical way to provide enough protection and shelf life for most consumers products. And here, we are going to explore more of the metallized foil structures

Metallized Foil Structures

To talk about the different metallized foil structures, we will have to differentitate the metallized substrate film, with common items as below.

- VMPET film (most used)

- VMCPP film

- VMBOPP Film

- VMPE Film

VMPET film based foil structures

VMPET film is able to provide numerous varaints in foil structures, as both sides can be laminated with other film materials, with most common items as below.

- (Matte)BOPP/VMPET/PE

- (Matte Laquer)/PET/VMPET/PE

- (Matte Laquer)/PA/VMPET/PE

- KPET/VMPET/PE

- (Matte Laquer)/PET/KPET/VMPET/PE

in some of the above foil structures, the inner PE film can be replaced by CPP film against customer requirements.

VMCPP film based foil structures

VMCPP film is enabled with bright metallized layer on one side, and heat sealable property on the other side, so generally, it works as the inner layer in the laminate foil, with common items as below.

- PET/VMCPP

- BOPP/VMCPP

As the toughness for these two layers foil are not so great, so usually, they are made into foil laminates, and works on the fill-form-seal machine and finalized into different packages, see potato chips pillow package as below.

VMBOPP film based foil structures

When VMBOPP film is applied into the package foil, it can be used alone,

VMPE film based foil structures

VMPET is very limited in the flexible packaging applications, as the adhesion of metallized layer LDPE film is very low (Read more: Check the bonding strength of metallized layr onto substrate film), and not able to finalize foil laminate with good bonding strength. The common structures with VMPE film base are as below

- PET/VMPE film

Without good bonding strength, this foil laminate can only be intended for light-weight products package, such as dehydrated vegetables.

Property

The properties for the metallized foil laminate are different for each specific structure, which should be discussed in details against each item, however, they have something in common, with list as below.

- Good barrier property than common plastic film

- Sunlight shielding

- Better vivid print effect as of the metallized background

Cost Considerations

Metalized foil laminate is of much lower cost than aluminum foil laminate with the same thickness. As the price for VMPET film is only 1/2~1/3 of the aluminum foil price. Based on the conditions where VMPET film can meet the required performance, most customers would prefer to choose metallized foil laminate. You are welcome to reach us for specific quote when you have enquiry.

Ok, that’s the basic things about metallized foil laminate, welcome to reach us whenever you have other questions.