As sustainability becomes a central theme in coffee packaging, biopolymer materials such as PLA (polylactic acid) are increasingly discussed as alternatives to conventional fossil-chemmical plastics. Among various feedstocks, cassava starch has emerged as an important renewable source for PLA production. For coffee brands and roasters, understanding how PLA is actually derived from cassava starch is critical to making informed packaging decisions.

As a reliable flexible packaging converter, we believe transparency in material science is essential. In this article, we will explain the step-by-step process of converting cassava starch into PLA, why this process matters, and how it influences PLA’s performance in coffee packaging applications.

What Is PLA?

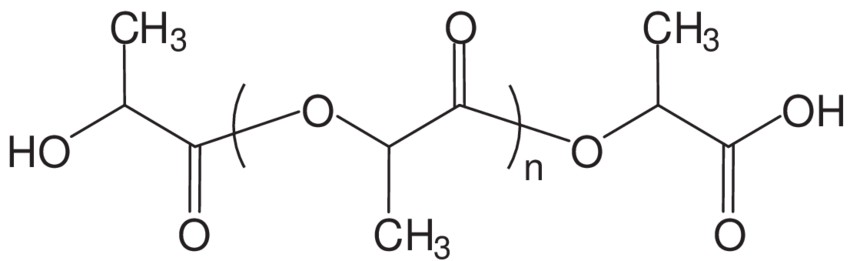

PLA (Polylactic Acid) is a bio-based and biodegradable thermoplastic polymer made primarily from renewable plant resources, such as corn starch, sugarcane, or cassava starch. It is one of the most widely used bioplastics in packaging, including coffee packaging applications.

Why Cassava Starch Matters?

Cassava starch is particularly attractive as a feedstock because:

- Cassava has a high starch yield

- It grows in tropical climates with relatively low input

- It does not compete directly with wheat or rice in many regions

From a sustainability perspective, cassava-based PLA offers a renewable carbon source, reducing reliance on petroleum-based polymers.

Step 1: Extraction of Starch from Cassava Roots

The PLA derivation process begins at the agricultural level.

Cassava roots should be washed and peeled, and then mechanically ground, and processed to separate starch from fiber and protein.

The resulting product is refined cassava starch, consisting mainly of polysaccharides (amylose and amylopectin). At this stage, cassava starch is not plastic—it is simply a carbohydrate resource.

Step 2: Hydrolysis – Converting Starch into Fermentable Sugars

Starch molecules are too complex to be directly fermented. They must first be broken down into simple sugars, primarily glucose.

This is achieved through enzymatic hydrolysis:

- α-amylase breaks long starch chains into dextrins

- Glucoamylase further converts dextrins into glucose

The output is a glucose-rich solution, suitable for microbial fermentation. This step is crucial, as sugar purity directly impacts fermentation efficiency and final polymer quality.

Step 3: Fermentation – Producing Lactic Acid

The glucose solution is then fermented using lactic acid bacteria, typically from the Lactobacillus family.

During fermentation, glucose is metabolized into lactic acid. The temperature and pH are tightly controlled to achieve better optical purity.

For flexible packaging converters, this step determines whether PLA can be processed reliably into film.

Step 4: Purification of Lactic Acid

Raw lactic acid obtained from fermentation contains water, residual sugars, biomass and organic impurities. Before polymerization, lactic acid must be filtered, concentrated, and chemically purified.

High-purity lactic acid is essential, otherwise chain termination can happen during polymerization with reduced molecular weight, and then finally weak film mechanical properties.

From a packaging performance perspective, purification quality directly influences seal strength and durability.

Step 5: Polymerization – Converting Lactic Acid into PLA

Purified lactic acid is converted into PLA through polymerization. The most common industrial method is ring-opening polymerization (ROP).

Key stages include:

- Condensation of lactic acid into lactide (a cyclic dimer)

- Purification of lactide

- Controlled polymerization into long-chain PLA molecules

In this stage, molecular weight, melt strength, thermal stability and processability will be defined

PLA produced via ROP offers better consistency and performance, making it suitable for extrusion, lamination, and pouch converting.

Step 6: PLA Resin Processing into Film

PLA resin derived from cassava starch is supplied in pellet form and processed into film through cast film extrusion or blown film extrusion.

Due to its rigidity and toughness, sometimes, it will have to be blended with other biopolymer such as PBAT, to achieve a more flexible film for various applications.

Conclusion

Deriving PLA from cassava starch is a complex, multi-stage biochemical and polymerization process that transforms a natural carbohydrate into a functional thermoplastic. Each step—from starch extraction to polymerization—directly influences PLA’s performance in flexible packaging.

For coffee brands and roasters, understanding this process helps set realistic expectations. Cassava-based PLA can support sustainability strategies when applied correctly, but it must be engineered thoughtfully to protect coffee quality.

As a flexible packaging converter, our role is to ensure that material science, packaging performance, and brand responsibility move forward together. You are welcome to reach us for further support when you want to customize your own packaging based on PLA film.