As sustainability reshapes the global coffee industry, packaging materials are under increasing scrutiny. Coffee brands today must balance product protection, shelf appeal, and environmental responsibility—often under pressure from both regulators and eco-conscious consumers. Among the emerging alternatives to conventional plastic materials, cellulose film has gained significant attention. Derived from renewable plant sources, cellulose film offers a compelling combination of biodegradability, transparency, and functional performance.

As a reliable flexible converter that is enaged in the coffee packaging field for more than 15 years, we are going to explore cellulose film in coffee packaging applications, examining its material properties, performance characteristics, limitations, and how it fits into modern sustainable packaging strategies.

What Is Cellulose Film?

Cellulose film is a bio-based packaging material made from natural cellulose, typically sourced from wood pulp or cotton linters. Through chemical processing and regeneration, cellulose is converted into a thin, flexible film commonly known in the market as cellophane or regenerated cellulose film.

Why Coffee Brands Are Interested in Cellulose Film

Unlike petroleum-based plastics, cellulose film originates from renewable resources and is designed to decompose under appropriate conditions. This makes it attractive to coffee brands seeking plastic-reduction or compostable packaging solutions.

Home Compostable and Biodegradable

Cellulose film can degrade under various conditions, like nature soil, seawater, wild conditions, and human city system. It is considered the highest level of eco-friendly packaging material like kraft paper, however remain clear transparent.

When using cellulose film, it is critical to ensure sustainability claims are accurate and verifiable. The cellulose film we adapt are in full compliance with EC 13432 standard and ASTM D6868. It is certified home compostable and industrial compostable by third-party TÜV Austria and DIN CERTCO. It also works with Forest Stewardship Counsil in the USA market.

Printability and Visual Appeal

Cellulose film is high transparent, with similar printability and properties of PET film, which can work so great when it is applied on the outer layer as print substrate. It proves to be one of the ideal substrate for high-definition gravure printing, sharp text and fine details and strong color reproduction.

For specialty and premium coffee brands, cellulose film offers a way to align packaging with sustainability storytelling without sacrificing visual quality.

Challenges of Cellophane Film Required by Coffee Packaging

The biggest challenge of cellulose film when intended for coffee packaging is the high-barrier properties required by coffee products, which is absolutely essential to preserve the product in original freshness and aroma until it is delivered to the consumers’ hands.

Cellulose film provides good oxygen barrier performance, however it is very sensitive to humidity, and can not protect coffee from the damaging moisture in the environment. So, barrier coating and metallization has to be applied onto cellulose film, and multilpe-layer laminate will have to be acheived when it is intended for coffee packaging.

Metallization of Cellulose Film

Vacuum metallization is a process in which a very thin layer of metal—typically aluminum—is deposited onto the surface of a film inside a vacuum chamber. It will just use no more than 1% of the normal aluminum foil, however achieves a high-barrier metallized layer which can be enough to preserve the fragrance and aroma of coffee products.

Of couse, vacuum metallized can be achieved on the surface of cellulose film, and you can have a further understanding on the thickness of metallized layer and its optical density by below table.

| Optical Density (OD) | Approx. Al Thickness | Barrier Quality | Typical Use |

|---|---|---|---|

| 1.8 – 2.0 | ~20–25 nm | Low–moderate | Decorative, non-barrier |

| 2.0 – 2.3 | ~25–35 nm | Moderate | Dry snacks |

| 2.3 – 2.6 | ~35–45 nm | Good | Coffee, tea |

| 2.6 – 3.0 | ~45–60 nm | High | High-barrier coffee |

| >3.0 | >60 nm | Diminishing returns | Rare, cost-inefficient |

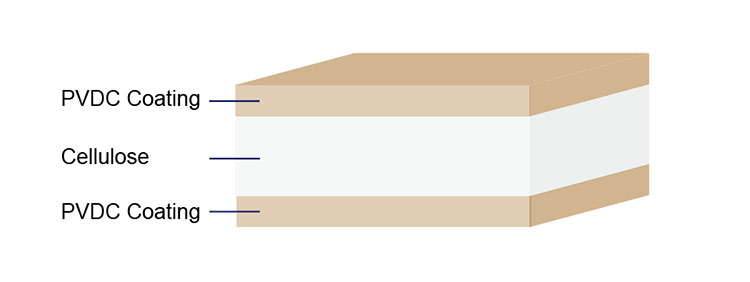

PVDC Coating Over Cellulose Film Surface

PVDC (polyvinylidene chloride) coating is a classic and highly effective barrier technology used to upgrade regenerated cellulose film from a moisture-sensitive material into a balanced oxygen and moisture barrier packaging substrate. Against the exact demand, PVDC coating can be applied on one side or both sides of the cellulose substrate. When it is applied for coffee packaging, usually two-sides coated cellulose should be the ideal choice, as it is able to provide a better protection of cellulose against the moisture in the environment.

It has a long history in food packaging, including coffee, confectionery, and dry foods.

Barrier Performance of Various Cellulose Films

| Property | Plain Cellulose | PVDC-Coated Cellulose | Metallized Cellulose |

|---|---|---|---|

| OTR (23 °C / 50% RH) cc/m²·day | 10–50 cc/m²·day (humidity-dependent) | 1–5 | 2~3 |

| WVTR (38 °C / 90% RH) g/m²·day | Very high | 5–10 | 4~5 |

| Aroma barrier | Moderate | Very good | Very Good |

Common thickness of Cellulose Film in Flexible Packaging

Cellulose film density is relatively stable, so thickness and weight correlate closely. To well understand the items available and on the other hand to control the cost, we list the common thickness of cellulose film and its gsm in below table.

| Nominal Thickness | Basis Weight (g/m²) | Typical Micron (µm) | Notes |

|---|---|---|---|

| 20 µm | ~28–30 g/m² | 20 µm | Very thin, limited mechanical strength |

| 23 µm | ~32–34 g/m² | 23 µm | Common for twist wrap, sachets |

| 25 µm | ~35–38 g/m² | 25 µm | Widely used packaging grade |

| 30 µm | ~42–45 g/m² | 30 µm | Better stiffness and handling |

| 35 µm | ~48–52 g/m² | 35 µm | High-strength cellulose film |

| 40 µm | ~55–60 g/m² | 40 µm | Specialty / laminated structures |

When cellulose film is applied to coffee packaging, usually we choose the thickness from 20 to 30 microns, balancing the properites and cost.

Common Coffee Packaging Structures Using Cellulose Film

Cellulose film is rarely used alone for coffee packaging. Instead, multilayer laminates are now developed to well meet the needs in the coffee packaging industry.

| Foil Laminate | Description | Coffee |

| PVDC coated Cellulose/PLA+PBAT | Two layer with limited barrier | * |

| Cellulose/AL/Poly Coating | Plastic reduction and easy tear | ***** |

| PVDC coated Cellulose/Metallized Paper/PLA+PBAT | Reinforced with PVDC coating and metallized layer, Triplex and compostable | **** |

| PVDC coated Cellulose/Metallized Cellulose/PLA+PBAT | Reinforced with PVDC coating and metallized layer, Triplex and compostable | **** |

| Kraft Paper/Metallized Cellulose/PBS | One layer of metallized, home compostable | *** |

| Metallized Paper/Metallized Cellulose/PBS | Two layers of metallized, home compostable | **** |

These structures are designed to balance sustainability with functional performance, including sealing strength, barrier protection, and machinability on form-fill-seal lines.

Compatibility with Coffee Packaging Formats

The multilayer cellulose laminate can be futher converted into various formats of coffee packaging, like flat bottom pouch, bottom gusseted doypack, quad seal pouch, and side gusseted bag. Of course, rolls can be used to run on Vertical-Form-Fill-Seal machinery to achieves kinds of sachets intended for ground coffee.

Conclusion

Cellulose film represents a meaningful step forward in sustainable coffee packaging. With its renewable origin, strong visual appeal, and improving barrier technologies, it offers coffee brands an opportunity to reduce environmental impact while maintaining premium presentation.

When thoughtfully engineered within multilayer structures, cellulose film can meet the functional demands of coffee packaging and support powerful sustainability narratives. As material innovation continues, cellulose film is poised to play an increasingly important role in the future of eco-conscious coffee packaging.

You are welcome to reach us whenever you want to explore more details how cellulose film can boost your business.