A variety of packaging bags bring great convenience to our daily lives. Stand-up bags are particularly popular for their sophisticated design and practicality.

Stand-up bags are widely used in industries like food and beverages. They stand upright on a flat surface, making them convenient for storage, display, and transportation. One popular type of packaging among sports enthusiasts is the gym spout bag, highly regarded for its convenience and user-friendly design.

This raises an interesting question: What materials are gym spout bags made of?

Let’s explore the details of this type of stand-up spout pouch.

Packaging Foil Materials

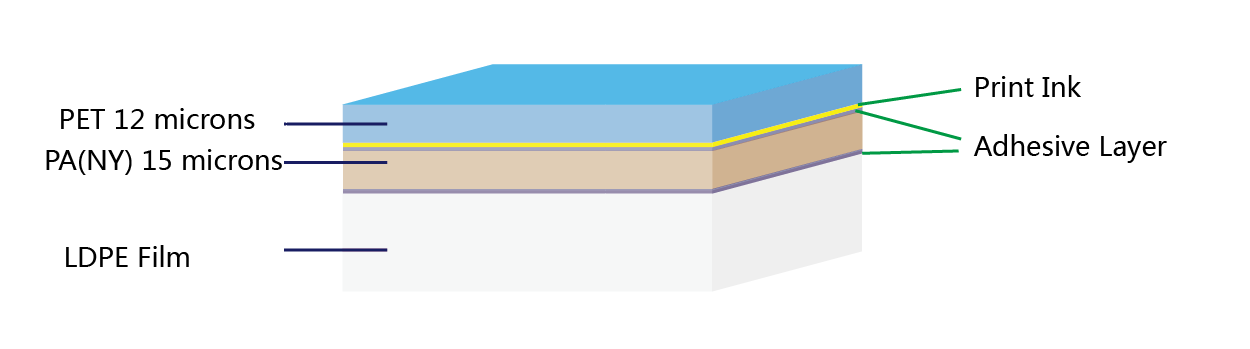

It is made of three layers, with the outside PET film as the print substrate film, the PA film as the middle reinforced layer, and finally, the LDPE film as the inner sealing layer.

Next, let’s get a deeper understanding of each substrate film material.

PET Film

PET Film in Packaging Applications

PET film, also known as polyester film, is widely used in the packaging industry , especially in flexible packaging bags,due to its outstanding properties.

Strength and Durability , PET film offers high tensile strength and toughness, making it resistant to tearing or damage during handling and transportation. This ensures the protection of the packaged contents.

Clarity and Product Visibility , With excellent transparency, PET film enhances product presentation by allowing consumers to clearly see the items inside.

Chemical and Barrier Performance , PET film resists most chemical substances and maintains stability across various environments. Its strong barrier properties protect against moisture and oxygen, extending product shelf life , particularly for food items.

In packaging bags, PET film is often used as the outer layer or intermediate layer, typically laminated with other materials to enhance overall performance. It is common in food packaging (e.g., snack bags, beverage bottle labels) as well as non-food applications like electronics.

In the flexible packaging industry, PET film is typically 12 microns thick (0.48 gauge), often referred to as PET12 or 0.48g PET. Among the many packaging formats, stand-up pouches , often made with PET film , remain a favorite for their unique design, stability, and functionality.

Stand-up pouches are widely used in the food and beverage industry for their ability to stand upright on flat surfaces, making them easy to store and display. A popular variation is the gym water spout pouch, valued for its convenience and user-friendly design.

Now, let’s explore the materials used to create juice spout pouches and delve into the details of this type of stand-up spout pouch.

BOPA Film

As a widely used packaging material, nylon plays an important role in the production of packaging bags thanks to its multiple advantages.

First, nylon offers high strength and toughness, making it resistant to breakage even when carrying heavy loads or subjected to pressure during transportation—effectively protecting the contents. Second, it has excellent wear resistance, ensuring durability when bags are handled or rubbed against various surfaces. Third, nylon provides chemical resistance, maintaining stability when exposed to many chemical substances, which makes it suitable for packaging products with diverse properties. Additionally, it offers good gas barrier properties. While not as strong as specialized barrier materials, nylon can still reduce gas penetration and help extend the shelf life of food products.

In terms of applications, nylon is commonly used in food packaging—for example, for nuts, dried meats, and other products requiring protection and preservation. In the industrial sector, it is used to package parts and raw materials for protection. It is also popular in express delivery packaging due to its strength and ability to withstand the rigors of transportation.

LDPE Film

LDPE (low-density polyethylene) is the most widely used inner sealing layer for stand-up juice pouches. It is lightweight, easy to process, and offers excellent chemical resistance, impact resistance, and durability. Being recyclable, reusable, non-toxic, and non-contaminating, LDPE is a preferred alternative to traditional plastics.

Another advantage is its customizability , the LDPE film can be tailored to meet specific product requirements, ensuring strong seals and reliable protection. The film thickness is determined based on the intended application, balancing strength, flexibility, and performance.

Great Standup Effect

In the gravure printing process, customer artwork is applied to the first layer of PET film. The film is then combined with two additional layers through either dry or solvent-free lamination, resulting in a finished laminated foil material.

A common structure is PET12/BOPA15/LDPE, often used for stand-up gym water bags. So, how does this structure perform in transit? Will it break?

PET film offers excellent stiffness, giving bags a strong stand-up effect. For smaller volumes under 500 ml, a simpler PET12/LDPE laminate can also provide adequate support. When aluminum and BOPA layers are added, the overall rigidity of the laminate increases, ensuring the bag maintains its upright shape and performs reliably during transport.

If you would like to get a better standing effect for your spout doypack, please just use three layers doypack, such as PET/PET/PE, or PET/PA/PE, this is the most best effect upon our experience.

Mechanical Property

The gym water product will be securely protected in durable spout packaging throughout filling, transportation, and distribution. Engineered to withstand extreme conditions, the pouch will not shatter during unexpected impacts such as delivery shocks or falls from shelves.

At our manufacturing facility, the mechanical integrity of our gym water stand-up sachets is a top priority. Our rigorous quality control system ensures every order meets the highest standards.

One of the most reliable ways to verify durability is the drop test , conducted on filled packages to confirm they can endure sudden, sharp impacts without bursting.

Barrier Performance

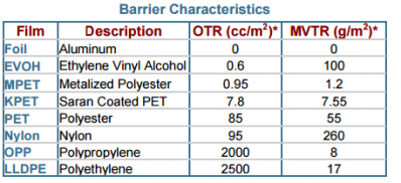

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The juice product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that, the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of juice products. The below table shows the typical value of the WVTR and OTR of this triplex foil laminate PET12/BOPA15/LDPE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

It is easy for the customers to understand this foil laminate is not of excellent barrier performance, as there is not any high barrier film layer in this foil structure. For some customers who have higher requirements for the flavors and freshness of their juice products, a foil laminate with higher barrier properties is inevitably needed.

In most cases, a layer of vacuum-metalized film, aluminum foil, or clear AlOx-coated polyester film is going to be included in the multi-layer foil materials. Through the below table, you can easily find out the typical values of moisture vapor transmission rate and oxygen transmission rate of common substrate film materials.

If you want to get a further understanding of this PET12/BOPA15/LDPE laminated foil, you may just read here.

Sustainable Materials Options

Compostable Packaging Materials

With the growing environmental impact caused by discarded fossil-based polymer materials, there is an unprecedented demand for sustainable packaging solutions. This shift encourages businesses to adopt more eco-friendly practices. Recent research in the juice market shows that an increasing number of consumers prefer products that demonstrate a commitment to environmental sustainability.

Compostable packaging materials are very similar to biodegradable ones, and often people confuse the two. In general, compostable materials are a subset of biodegradable materials that break down without releasing harmful substances into the environment.

Regarding the materials used in our factory, customers can generally consider biodegradable and compostable materials as equivalent.

These materials are typically derived from biomass sources such as maize starch, cassava, sugarcane, or plant-based fibers like cellulose. The resulting resins, known as biopolymers, decompose into inorganic components through the natural action of bacteria, algae, and other microorganisms.

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, actually fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Now, the mono-materials recyclable spout sachet can be well intended for gym water from 50~250 ml, with the barrier performance as good as traditional metalized film spout doy-pack. That’s good enough for the packages of gym water products.