In the years passing by, concerns over the environmental burden of plastic package produce have grown remarkably, which has led the coffee roasters to seek more eco-friendly packages for their products. Of course, there are some available divisions when it comes to eco-friendly, with compostable coffee package, fully recyclable coffee package dominating the current commercial market.

Compostable packaging materials are made using plant-based resources such as corn, sugarcane, or bamboo, plant fiber, seems more attractive to some well-known brands, as the produce, process, and composting procedure of these plant-based film materials seems more accessible.

In this post,we will give an orverall introduce of the plant-based film materials for coffee bag packaging available under current technology.

Kraft Paper

Kraft paper is a lightweight, cost-effective, and eco-friendly packaging film material widely applied in flexible packaging, which can be well intended for a wide range of products, like foods, snacks, dry nuts, coffee beans, phamaceutical items. Made from wood pulp and plant fiber, kraft paper is biodegradable and home compostable in natural conditions.

The natural color of kraft paper is usually brown, of course, with some color tolerance like red, hazel, as of the different woods. White kraft paper appearance will be achieved after bleaching process, which is highly appreicated by many roasters.

When kraft paper packaging is completely compostable at home, it further engages customers in the recycling process.

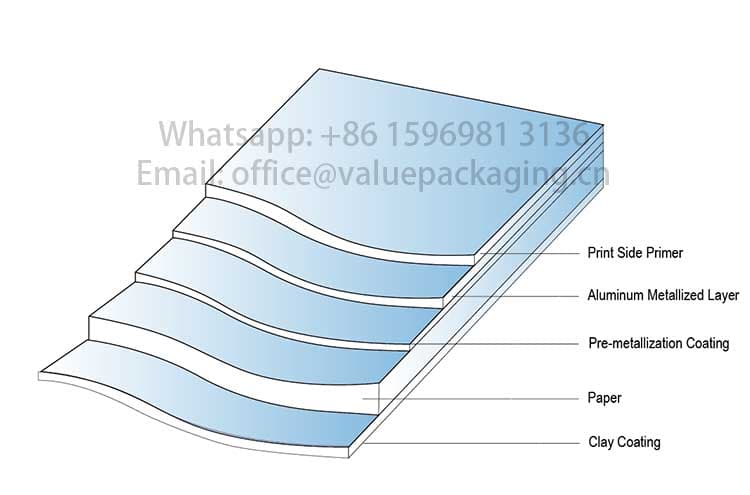

Metallized Paper

Based on kraft paper substrate, a thin layer of aluminum can be coated on the surface with matte or gloss effect, that can provide a decorative and protective property.

Clay coating, pre-metallization coating and aluminum metallized layer is processed onto the kraft paper substrate, which can be considered as compostable film substrate.

The thickness of top aluminum layer is around 400~600 Ångstrom, which is only 0.04~0.06 um. When exposed in nature conditions, the aluminum will react with moisture and oxygen into AlOx inorganic material, so metallized paper should be considered as home compostable material.

With great mechanical property, good printablity and processing stability, metallized paper can be laminated with other biomaterials to achieve high barrier multi-function foil laminates, with some common items as below.

- Metallized Paper/Cellulose/PLA+PBAT Film

- Metallized Paper/AlOx Coated Cellulose/PLA+PBAT Film

- Metallized Paper/Metallized Cellulose/PLA+PBAT Film

- Cellulose/Metallized Paper/PLA+PBAT Film

- Metallized Paper/PLA+PBAT Film

- Metallized Paper/BOPLA Film

All these above foil structures are of higher barrier performance against non-metallized foil laminate, which can be well intended for roasted coffee beans packages.

Customer artwork can be printed on the paper side or aluminum side of the metallized paper substrate, in flexo printing, offset printing and rotogravure printing.

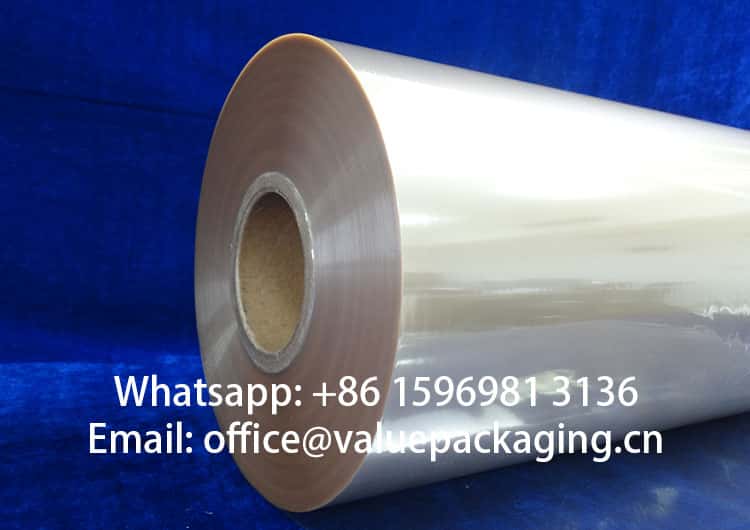

Cellulose Paper Film

Cellulose paper film is a clear transparent film manufactured from pulp, and the pulp is made by breaking down the cellulose fibres of plant, so cellulose paper is considered as the typical plant-based film materials. It will degrade into inorganic elments in nature conditions in 30~90 days.

Cellulose film is highly appreciated in the coffee packaging market as of below excellent property

- Home compostable

- Good clarity

- Good printability

- Excellent mechanical property

- Processing stability

Based on above properties, printing, coating, laminating and metallization process can be well done on cellulose paper. Cellulose-based composite foil material can be achieved to meet the various requirements of roasted coffee beans, like oxygen barrier, fragrance protection, robust package, good standing profile, etc.

Below picture shows the amazing profile of 12oz compostable block bottom bag that is achieveed based on Cellulose film materials, with foil structure Cellulose/20/Metallized Paper69gsm/PLA+PBAT50um.

Colorful artwork is well printined on to the inner side of cellulose paper, with a further matte lacquer coating applied on the outside, quite attractive, right?

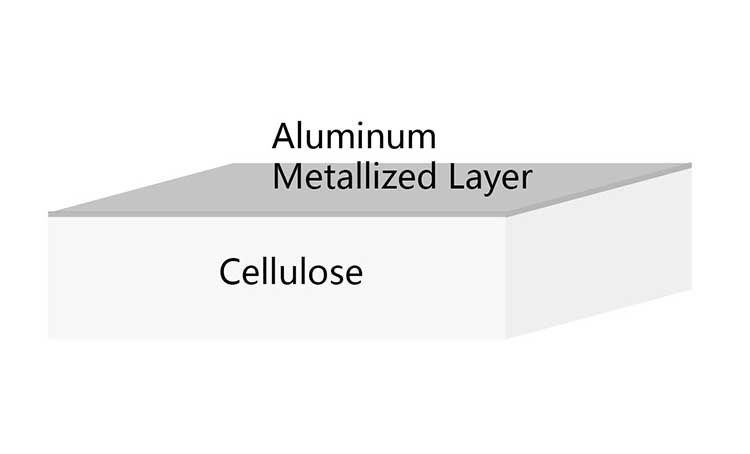

Metallised Cellulose Film

Luckily, we have metallized cellulose film in application for coffee packaging, which makes the cofffe packages good protection for the roasted beans, and keep them in original flovor in a prolonged period.

Metallised cellulose film is to apply a thin aluminum layer coating onto the surface of cellulose paper, with enhanced barrier performance against oxygen, water vapor, sunglight and fragrance.

When it comes to the high barrier coffee packaging, Metallised cellulose film usually works as the middle layer. Not only it improves the barrier protection for the products, however it increases the stiffness for the foil materials, which will finally create an excellent standing profile for the coffee packages.

The glossy metallic standing pouch in below picture is made of foil laminate Cellulose30/Metallized cellulose20/PLA+PBAT50, with great standing up effect, and quite suitable for coffee packages.

Rice Paper

Rice paper, like kraft paper, is a similar substrate paper material made from plant fibers. It is with fantastic texture and hand feeling, that cause people to apply it into packages for many products, like foods, snacks and coffee beans.

Below pictures shows the finsihed standing up zipper doypack made from rice paper, with a clear front window showing the products inside.

PLA Film

PLA is short for Polylactic acid, which is a thermoplastic monomer derived from renewable, organic sources such as corn starch, cassava or sugar cane, that is also considered as plant-based film material.

PLA resin can be processed into film membrane, with good clarity and printability, which can be used for the flexible packaging industry. However, as PLA is lack of elasticity, the finished BOPLA film is tough and stiff, and it may make so much noise just by flipping the film.

However, BOPLA film is quite limited to the coffee packaging as of some bad properties, like bad barrier performance, unable to withstand high temperature, too stiff, and bad sealing strength, and of course, we will share our experience in future posts.

OK, that’s the basic plant-based film materials in current market, and based on that, we develop our compostable coffee packaging, biodegradable coffee packaging, which improve the environmental sustainablitity for the coffee branding.

Wow, what an enlightening read! It’s incredible to see how sustainable practices are making their way into every aspect of our lives. I’m thrilled to learn about the various plant-based film materials that are now being used for coffee bag packaging. Thank you for sharing this blog

Hello, we are glad to have your message here, and any questions regarding plant-based film materials, you may just reach us for more assistance