The standing paper pouch is a popular choice for snacks, especially fried snacks. In today’s competitive snack market, packaging is often the first point of contact between a brand and its customers, and this type of pouch naturally fits that role. Its simple structure and familiar form make it easy for consumers to recognize and trust at a glance.

About the bag made of kraft paper and LDPE, this type of pouch does more than simply hold the product. Its upright structure allows it to stand confidently on the shelf, helping the product catch attention even in crowded retail spaces. For brands, this stronger shelf presence can make a real difference in whether a customer pauses, picks it up, and takes a closer look.

The wide front panel offers enough space to communicate key messages clearly, from brand identity to product highlights. For consumers, the pouch feels practical and comfortable to use. It is easy to open, easy to store after use, and suitable for both home and on-the-go scenarios.

Overall, this packaging choice combines visual appeal with everyday convenience, creating a positive experience that supports brand image and encourages repeat purchases.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

In this post, we will introduce details about the film structure used in the 250 g snack food: Kraft paper/LDPE. Hope it is helpful for people in need.

Packaging Foil Materials

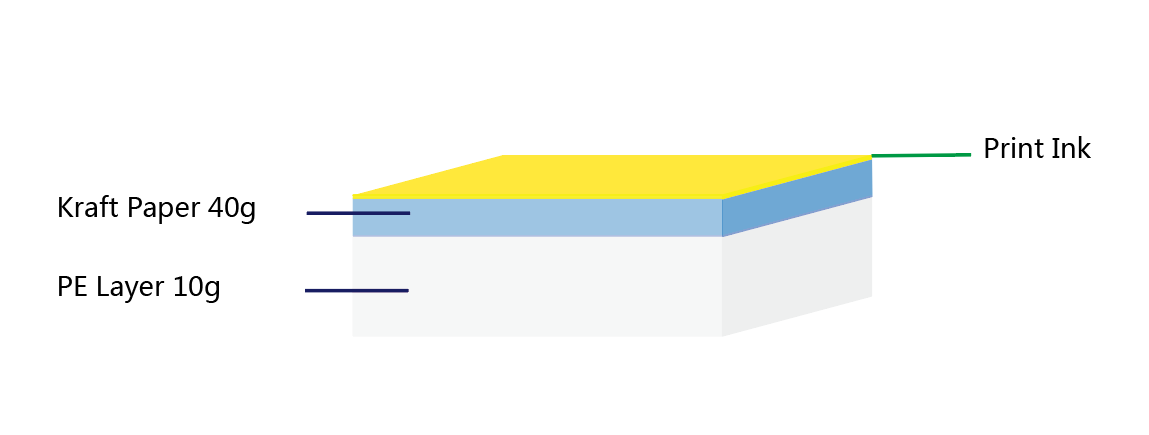

The figure below shows the composition structure of this laminated foil material (Kraft paper/LDPE) used to package snacks in food stand-up bags.

The bag is made of kraft paper and LDPE, combining the natural look and rigidity of paper with the moisture resistance and sealing performance of LDPE. Kraft paper provides structure, stiffness, and a natural appearance. LDPE acts as the inner layer, offering moisture protection, sealing performance, and helping keep the contents fresh.

Kraft paper film

Kraft paper is a durable paper made from wood pulp, with its name derived from the German word “kraft,” meaning “strength.” It is produced using the Kraft pulping process, in which wood chips are cooked under pressure to separate cellulose fibers, resulting in a strong and resilient pulp. The pulp is then formed, dried, and rolled into large sheets that can be cut and converted as needed.

Although kraft paper is commonly recognized for its brown color in paper bags or butcher paper, it can also be bleached to produce a white appearance. Compared with standard paper or cardboard, kraft paper offers higher strength and tear resistance, making it especially suitable for packaging applications.

In addition to packaging, kraft paper is widely used for other purposes, including:

• Lining particle boards

• Base paper for sandpaper

• Wrapping flower bouquets

• Electrical insulation in transformers

• Paper sacks for cement, food, chemicals, and consumer goods

• Flour bags

LDPE film

LDPE (Low-Density Polyethylene) is a widely used plastic material commonly applied in food packaging, consumer goods, and industrial products. In composite packaging, it often serves as the inner layer, providing moisture and oil resistance, as well as excellent sealing performance, while maintaining flexibility and durability. The main advantages of LDPE include:

- Low Cost: LDPE is one of the cheapest plastics available, making it a popular choice for a wide range of applications.

- Flexibility: LDPE is highly flexible, allowing it to be easily formed into a variety of shapes and sizes.

- Toughness: LDPE is highly resistant to impact, making it suitable for use in applications where it may be subjected to mechanical stress.

- Chemical Resistance: LDPE is resistant to many chemicals, making it suitable for use in applications where it may be exposed to harsh chemicals.

- Recyclability: LDPE is recyclable, making it an eco-friendly choice.

Great Stand-Up Effect

Kraft paper offers a good standing effect, giving bags and pouches the ability to remain upright on shelves. This stability not only makes the packaging more visually appealing but also improves product display and handling. The stiffness of kraft paper ensures that the bag keeps its shape even when partially filled, while providing a solid base that prevents tipping. When combined with an inner LDPE layer, the bag retains its standing ability while adding moisture resistance, ensuring both functionality and presentation are maintained.

Excellent Airtight Property for Zipper lock

The inner LDPE layer bonds tightly with the zipper, ensuring a strong, airtight seal. This makes it convenient for customers to repeatedly open and close the package while preserving the freshness of the contents over time.

Our quality control team carefully monitors the zipper’s sealing performance. You can see a detailed demonstration of the testing process in the video below.

Mechanical Property

This bag can be achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, based on customer requirements.

In our daily QC work, there is an easier and more reliable method to check if the bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, and distribution. We perform a drop test against each order. Of course, the standard for this drop test should be decided against customer needs.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (oxygen transmission rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, Kraft Paper/LDPE foil laminate will be able to meet most of the requirements for platinum chips. WVTR (short for water vapor transmission rate) and OTR (oxygen transmission rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 1.25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.36 |

More Sustainable Materials Options

As concerns over plastic pollution continue to grow, more brands are turning their attention toward sustainable packaging options. Solutions such as compostable packaging, recyclable mono-material structures, and packaging made from plant-based materials are gaining wider adoption across the industry.

Compostable Packaging Materials

In recent years, compostable packaging has become an important direction for brands aiming to reduce environmental impact. Unlike conventional plastics, compostable materials are designed to return to nature after use, breaking down without leaving persistent residues when handled under suitable conditions.

The compostable materials we use are sourced from renewable, plant-based resources such as cellulose and agricultural biomass, including corn, cassava, and sugarcane. These resources are processed into bio-based resins that can be decomposed by naturally occurring microorganisms, helping close the loop between packaging use and environmental recovery.

At our facility, compostable stand up pouches and roll materials are developed with both performance and sustainability in mind. Each structure is adjusted to match the specific needs of the packaged product, balancing protection, usability, and environmental responsibility.

Compared with the higher cost of compostable foil materials, fully recyclable sachets and roll films are becoming the preferred choice due to their cost efficiency and suitability for lightweight packaging. Advances in PE barrier technology now allow foil-free recyclable laminates to provide effective moisture protection for products such as sunflower seeds, while additional PVA coatings on LDPE or HDPE films can further enhance moisture resistance. For applications requiring stronger oxygen barriers, integrating an EVOH layer into BOPE films delivers reliable performance, making these structures well suited for modern flexible packaging.

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, actually fully recyclable material sachets and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono-material packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending up in landfills.

If you have any questions or would like further information about our juice pouch packaging solutions, don’t hesitate to get in touch.

Wishing you have a good day!