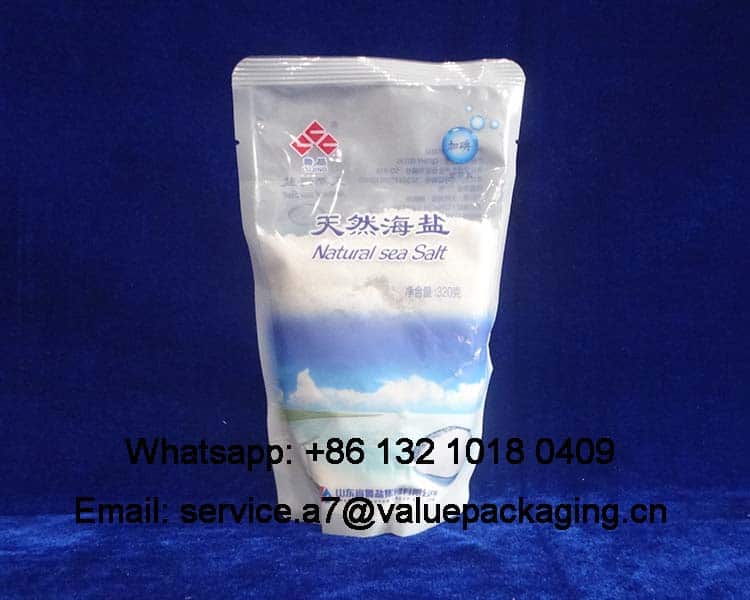

Stand-up pouches are a popular packaging solution for dry goods such as sea salt, sugar and seasonings. With a gusseted bottom, the pouches stand upright on the shelf, providing better visibility and a neat display in a retail environment. This packaging format is particularly suitable for products that are used once or in limited quantities and do not require resealing.

Made of durable multi-layer composite film, the stand-up pouches effectively protect against moisture, oxygen and external contamination, helping to keep the product fresh during transportation and storage. The high-quality outer packaging can be printed to facilitate the communication of brand, product details and origin information in a clear and beautiful way.

Combining functionality, visual appeal and efficient material utilization, stand-up pouches are a reliable and affordable packaging choice for domestic and international markets.As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, which are listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- Vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- Biodegradable film materials

- Compostable substrate films

- Fully recyclable substrate films

In this post, we will analyze the exact foil materials of this 320g salt standup bag, hoping it could serve as a reference for your products.

Ok, let’s get into the details of this standup bag.

Packaging Foil Materials

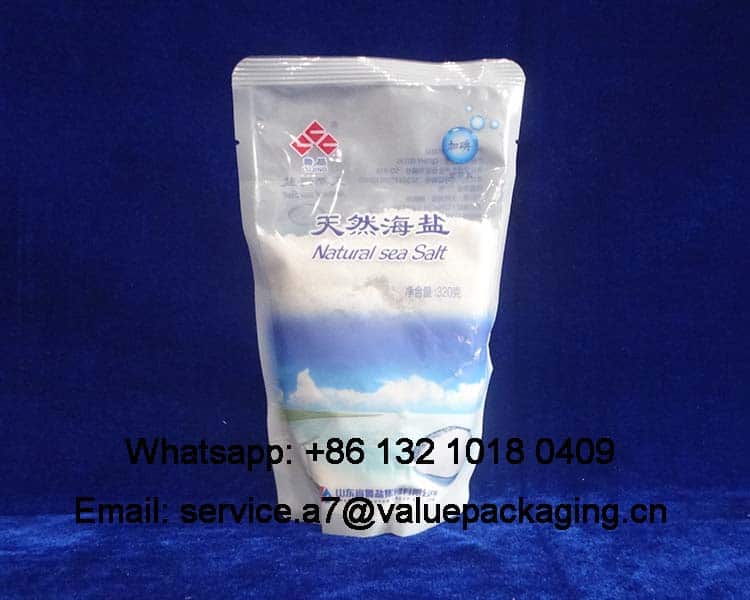

The figure below shows the composition structure of this laminated foil material used to convert this stand-up salt bag.

It is made of duplex layers, with the outer PET film 12 microns serving as the print substrate and providing excellent mechanical strength and surface clarity. The inner LDPE film 100 microns acts as the sealing layer, offering good heat sealability and protection against moisture. This PET12/LDPE100 structure is well-suited for 320g of salt, providing sufficient durability and barrier performance for it.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET film is one of the most widely used printing substrates in the flexible packaging industry. It offers excellent optical clarity, high gloss, good chemical resistance, stable mechanical strength, impressive dimensional stability, and outstanding printability. These properties not only allow it to display customer artwork with precision and vibrancy but also contribute significantly to the overall durability of the final package.

In the flexible packaging industry, the most commonly used thickness for PET film is 12 microns, which is equivalent to 0.48 gauge. Therefore, whenever you see references to PET12 or 0.48 g PET, you can understand that they refer to the same material.

LDPE Film

LDPE stands for Low-Density Polyethylene Film. It is the most commonly used inner seal in stand-up pouches. LDPE is lightweight, easy to process, and has good chemical and impact resistance. It is also recyclable, reusable, non-toxic, and durable.

The thickness of LDPE can be adjusted based on product needs. This helps ensure a secure seal and proper protection in different applications.

These 2 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/LDPE foil.

Thickness

As you can see below picture, the overall thickness of this stang-up pouch is 0.109 mm, which equals 109 microns for this laminated foil.

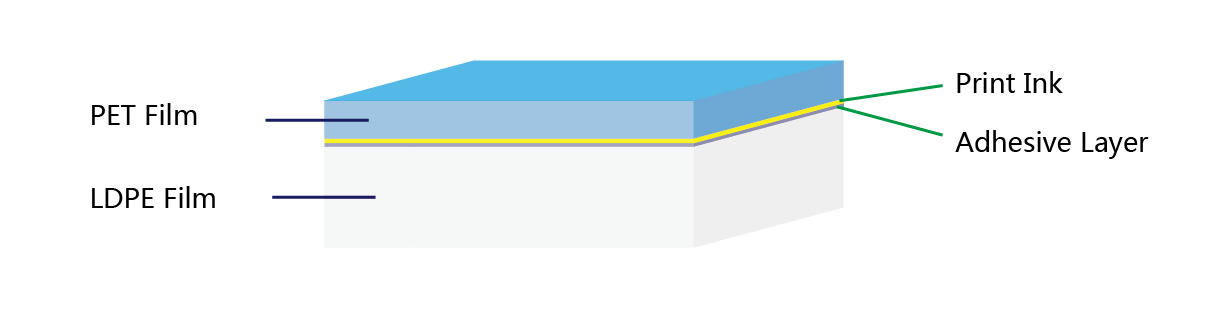

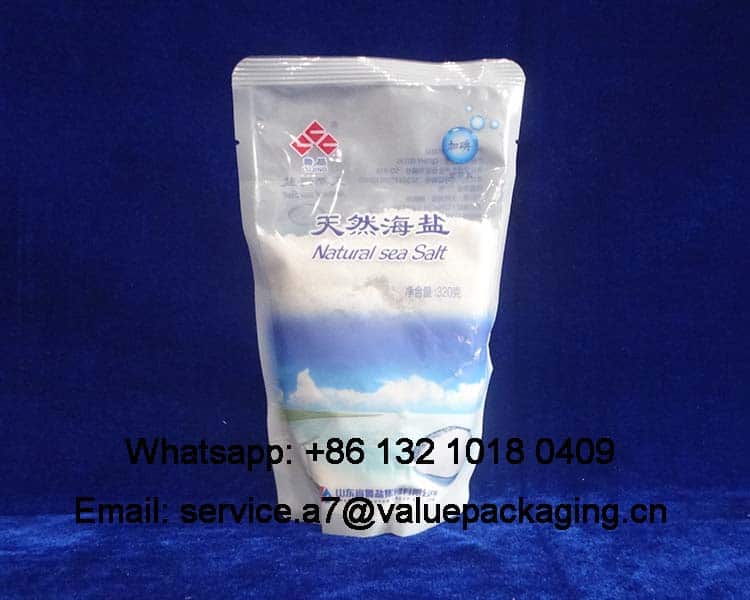

Great Standup Effect

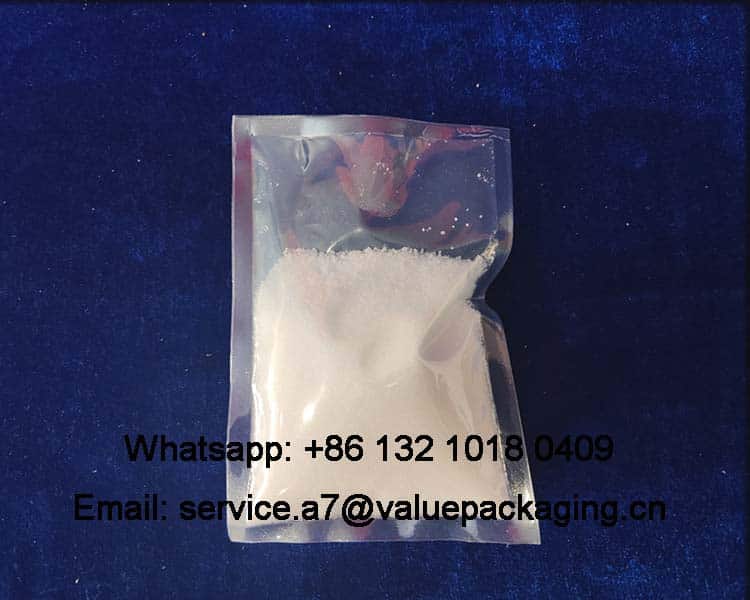

Through the pictures below, you may learn the standing effect when 320g of salt are filled into a stang-up bag based on this laminated foil PET12/LDPE.

Great Standup Effect

The stand-up packaging is designed to protect the salt during transport and distribution. It is able to withstand emergency situations such as unexpected transport shocks or the package falling off the shelf, ensuring that the package does not break. This prevents leaks and avoids salt particles from contaminating the floor or the box.

At our production facility, the mechanical integrity of the stand-up bag pouches of 320g salt is our top priority. Our quality control system implements strict measures to ensure that every order meets our expected standards.

In short, drop testing of filled packages is one of the most reliable ways to determine whether a package can withstand sudden impacts without breaking.

Here, we are going to fill 320g of salt into this bag, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

More Bag Type Options

We offer a wide range of pouch types to meet different needs for product display, use, and branding. As the market grows, brands want packaging that protects the product and shows its value. That’s why we provide various options—from stand-up pouches to flat-bottom bags—to fit different sizes, sealing styles, and storage needs.

Pillow Pouch

Pillow Pouch bags are a classic and efficient packaging form, widely used in the packaging of salts, powders, and granules. They can be used for high-speed automatic filling and packaging, which can greatly improve the efficiency of the production line.

4 Side Seal Pouch

The picture above shows a small bag with four side seal pouch. The small bag withfour side seal pouch is widely used in small package products. It can provide a complete double-sided display effect, provide sufficient printing area, and enhance brand recognition.

Now it’s the end. You are welcome to reach us if you have any questions regarding juice pouches. Have a nice day.