Spouted pouches are becoming an increasingly popular solution for ready-to-drink products like table wine. This 250ml pouch offers excellent portability, reduced packaging waste, and extended freshness through a secure, resealable cap.

By using a flexible multilayer film structure, the pouch protects the wine from oxygen and light during storage and transport—ensuring quality from shelf to sip. Custom printing on the pouch surface provides a full canvas for bold branding and legal labeling, making it a standout format for modern wine distribution.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

With a refined package dimension, this stand-up screw cap bag accommodates 150 ml wine liquids with an excellent filled level. It can present an excellent standing profile for the product on the goods shelves.

Ok, let’s get into the details of this standup screw cap spout bag.

Packaging Foil Materials

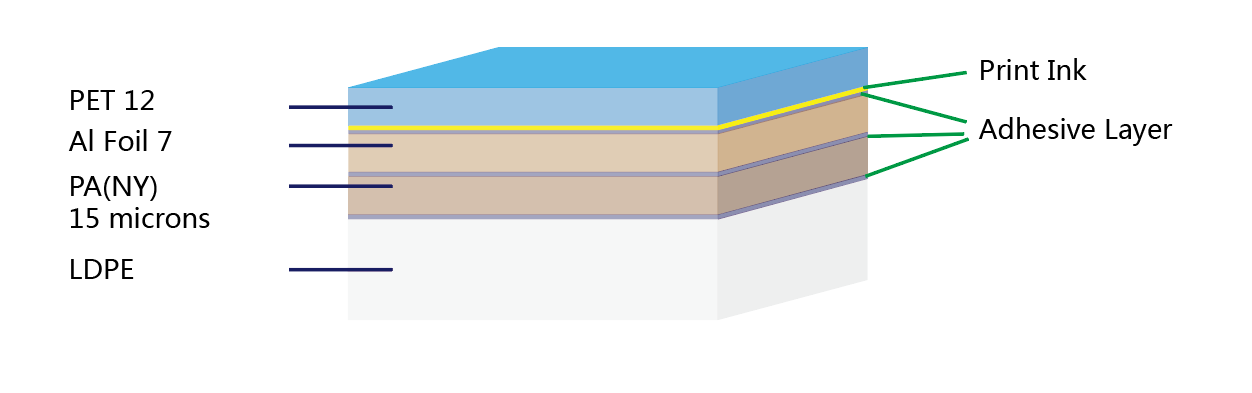

The figure below shows the composition structure of this laminated foil material which is used to convert this standup wine pouch.

PET Film

PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

Aluminum Film

Aluminum foil is a thin, pliable sheet of aluminum alloy that is often used for wrapping and covering food during cooking. It is made by rolling large slabs of aluminum until they are less than 0.2 millimeters thick, and then solidifying the molten alloy between water-cooled rollers.

Aluminum foil is 98.5% aluminum, with the remaining percentage primarily made up of iron and silicon to increase strength and puncture resistance. It has many properties, including: Durability, Non-toxicity, Oil-proofness, Chemical resistance, and Good thermal conductivity.

BOPA (Biaxial Orientated Polyamide Film)

BOPA stands for Biaxially Oriented Polyamide, which is also known as biaxially oriented nylon (short as NY) film. It’s a versatile and flexible material that’s made by biaxially stretching polyamide resins using a flat cast die process, three-layer co-extrusion method, and two-step tenter frame orientation.

BOPA film is especially popular for food packaging because it can help keep food fresh and can display important information like whether the product is organic, vegetarian, or halal, and if it contains allergens. The growing demand for packaged food and the pharmaceutical industry are expected to drive the growth of the BOPA film market in the coming years.

LDPE Film

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. It is often used for manufacturing plastic goods like cling wrap, juice containers, orthotics, and prosthetics.

LDPE is environmentally friendly, low-cost, and low-energy. However, it’s not suited for applications that require stiffness, high temperature resistance, or structural strength. LDPE also has limited resistance to some chemicals, such as aliphatic and aromatic hydrocarbons, mineral oils, and oxidizing agents.

The customer artwork is printed reversely on the inner side of the first PET film layer in the gravure printing system. Then, these 4 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Usually, we describe the finished laminate as PET12/AL7/BOPA15/LDPE foil. So, how does this foil structure perform when it is intended for wine stand-up spout bags? Will it break during the transit?

Great Standup Effect

PET film is of great stiffness, which makes it suitable for creating a good straight-standing effect for stand-up bags. For some low-volume packages of less than 500 ml, even PET12/LDPE foil laminate can create enough standing effects for most products. So, when there is an extra PET film layer applied in the middle of this foil laminate, the stiffness of this finished foil will be able to present a stand-up profile.

The video below explains the self-supporting spout packaging for red wine very well.

Mechanical Property

The spouted pouch is designed to protect juice products throughout filling, transport, and distribution. Even in unexpected situations—like sudden impacts during delivery or a pouch falling off a shelf—breakage is not an option. No one wants to deal with leaked juice soaking into cartons or spreading across the floor.

That’s why we place the mechanical strength of this 150ml red wine stand-up pouch at the forefront of our manufacturing priorities. Our quality control process follows strict protocols to ensure every order is delivered with consistent, reliable performance.

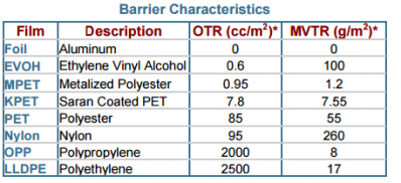

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The wine product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that, the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of wine products. The below table shows the typical value of the WVTR and OTR of this four foil laminate PET12/AL7/BOPA15/LDPE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 12.6 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 8.5 |

In most cases, a layer of vacuum-metalized film, aluminum foil, or clear AlOx-coated polyester film is going to be included in the multi-layer foil materials. Through the below table, you can easily find out the typical values of moisture vapor transmission rate and oxygen transmission rate of common substrate film materials.

so, a reinforced foil structures are better protections for the freshness and flavors of wine products, with available item listed below.

You may reach us for further ideas on each foil structure if you need any assistance.

Technical Data Sheet of 150ml wine standing bag

Here, we attach the specification sheet of this 150ml wine standup sachet based on foil laminate PET12/AL7/BOPA15/LDPE80.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET12/AL7/PA15/LDPE laminated foil, you may just read here.

Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the juice market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

Compostable packaging materials are closely related to biodegradable materials, and the distinction between the two is often unclear. In general, compostable materials are a type of biodegradable material that, when broken down, leave no harmful residues in the environment.

At our facility, the compostable materials we use can be considered functionally equivalent to biodegradable ones for most customer applications.

These materials are derived from renewable biomass sources such as maize starch, cassava, sugarcane, and plant-based fibers like cellulose. The resins extracted from them—commonly known as bio-polymers—can naturally decompose into non-toxic, inorganic compounds through the action of bacteria, algae, and other microorganisms.

We manufacture high-quality compostable stand-up sachets and roll films, customized to suit the specific requirements of different products.

If you’re exploring sustainable packaging options, feel free to reach out—we’re happy to provide more ideas and tailored solutions.

Fully Recyclable Mono Materials

While compostable foil materials tend to come with a higher cost, fully recyclable sachets and roll films have rapidly gained popularity in the lightweight packaging market due to their significantly lower price point.

These mono-material packages are composed of multiple layers made from the same base resin, making them much easier to recycle within standard waste processing systems. As a result, they offer a practical way to reduce the amount of plastic packaging ending up in landfills.

Today, mono-material recyclable spouted sachets are widely used for juice packaging in volumes ranging from 50 to 250 ml. With barrier properties comparable to those of traditional metallized spouted doy-packs, they offer reliable protection for juice products—without compromising sustainability or performance.

Of course, you are welcome to reach us if you have any questions regarding wine pouches. Nice day.