This stand up goji berry package is designed with a stable bottom gusset that allows the bag to stand upright on shelves, helping improve product visibility and shelf presentation. The structure is firm and well shaped, offering both practicality and a clean appearance.

The resealable zipper closure provides convenience for repeated use while helping maintain the freshness of the goji berries after opening. The packaging material offers good barrier performance to protect the product from moisture and external factors during storage and transportation.

With its balanced combination of functionality and visual appeal, this stand up pouch is suitable for dried fruits, goji berries, and other similar food products.

Based in Qingdao, China, we are a well established flexible packaging converter with strong access to and experience in utilizing the film materials available in today’s market, as listed below.

- Fossil-Based Chemical Polymer Films

- Aluminum Foil Metal Sheets

- Vacuum-Metalized Film Substrates

- Ceramic Film Substrates

- Plant-Based Biopolymer Materials

- Biodegradable Film Materials

- Compostable Substrate Films

- Fully Recyclable Substrate Films

In this article, we will introduce details about the exact film structure used in the 500g gojiberry. Hope it is helpful for people who want to improve their brand packaging.

Packaging Foil Materials

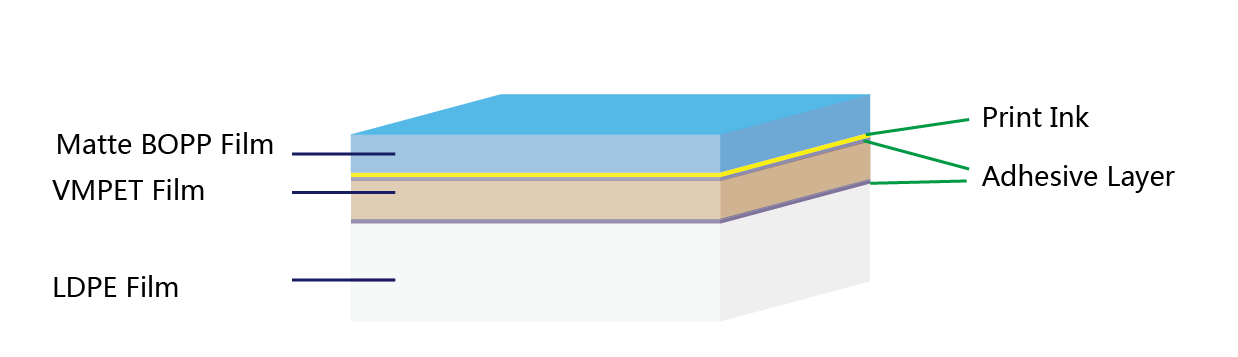

This stand-up gojiberry package made of MatteBOPP/VMPET/LDPE. The picture below display the composition structure of this laminated foil material.

Matte BOPP film

Matte BOPP, short for matte biaxially oriented polypropylene film, is a functional polymer film characterized by its soft matte surface. Unlike glossy films that reflect light, matte BOPP absorbs light, creating a smooth and low glare appearance. This visual effect helps reduce reflections under strong lighting and gives packaging a more refined and premium look. Because of this, matte BOPP film is widely used on the outer layer of packaging to enhance overall aesthetics and add a modern, fashionable touch to branded products.

The production of matte BOPP film involves an extrusion process followed by biaxial orientation, in which the film is stretched in both the machine direction and transverse direction. This orientation process enhances tensile strength, clarity control, and barrier performance. Matte BOPP film can be manufactured using either the tubular process or the tenter frame process, depending on the production setup and specific performance requirements.

VMPET film

VMPET film, short for vacuum metallized polyester film, is a functional packaging material produced by depositing an extremely thin layer of aluminum onto the surface of a PET (polyester) film substrate under high vacuum conditions. Through this vacuum metallization process, aluminum atoms are evenly distributed and bonded to the film surface, forming a continuous metallic layer that gives the film a bright, reflective appearance and a distinctive metallic sheen.

In addition to its visual appeal, VMPET film offers improved barrier performance compared to standard PET film. The aluminum layer enhances resistance to moisture, oxygen, and light, helping to protect packaged products from external environmental factors. This makes VMPET film especially suitable for applications where extended shelf life and product freshness are important.

LDPE film

LDPE, or low density polyethylene, is a thermoplastic polymer belonging to the polyethylene family. It is well known for its excellent flexibility, toughness, and clarity, making it suitable for applications that require softness and durability. LDPE is lightweight and easy to process, with good formability across a wide range of manufacturing methods.

In addition, LDPE offers strong resistance to chemicals, moisture, and corrosion, along with reliable impact resistance even at lower temperatures. These properties allow it to perform well in both packaging and industrial applications. As a result, LDPE is widely used in the production of various plastic products, including cling wrap, squeeze bottles and juice containers, as well as medical and healthcare items such as orthotics and prosthetics.

Great Standup Effect

This multi-layer structure, combining Matte BOPP, VMPET, and LDPE, provides the pouch with excellent durability and stand-up performance. The reinforced base ensures the bag remains upright on shelves, even when partially filled, maintaining a neat and attractive presentation.

The combination of Matte BOPP’s soft, low-glare surface and VMPET’s metallic layer creates a visually striking exterior that enhances shelf presence and brand appeal. Meanwhile, the LDPE inner layer offers reliable sealing, flexibility, and protection for the contents.

Excellent Airtight Property for Zipper lock

The inner LDPE layer adheres securely to the zipper, providing a reliable, airtight seal. This allows customers to open and close the pouch multiple times without compromising the freshness of the contents.

To ensure consistent performance, our quality control team rigorously tests each zipper for sealing strength and durability. A detailed demonstration of the testing process is available in the video below, showing how we maintain high standards for every package.

Mechanical Property

This bag can achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements.

Drop Test

In our daily QC work, there is a more easy and reliable method to check if the bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, and distribution. We perform a drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, MatteBOPP/VMPET/LDPE foil laminate will be able to meet most of the requirements for platinum chips. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 1.25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.36 |

More Sustainable Materials Options

As concerns over plastic pollution continue to grow, more brands are turning their attention toward sustainable packaging options. Solutions such as compostable packaging, recyclable mono material structures, and packaging made from plant based materials are gaining wider adoption across the industry.

Compostable Packaging Materials

In recent years, compostable packaging has become an important direction for brands aiming to reduce environmental impact. Unlike conventional plastics, compostable materials are designed to return to nature after use, breaking down without leaving persistent residues when handled under suitable conditions.

The compostable materials we use are sourced from renewable, plant based resources such as cellulose and agricultural biomass including corn, cassava, and sugarcane. These resources are processed into bio based resins that can be decomposed by naturally occurring microorganisms, helping close the loop between packaging use and environmental recovery.

At our facility, compostable stand up pouches and roll materials are developed with both performance and sustainability in mind. Each structure is adjusted to match the specific needs of the packaged product, balancing protection, usability, and environmental responsibility.

Compared with the higher cost of compostable foil materials, fully recyclable sachets and roll films are becoming the preferred choice due to their cost efficiency and suitability for lightweight packaging. Advances in PE barrier technology now allow foil free recyclable laminates to provide effective moisture protection for products such as sunflower seeds, while additional PVA coatings on LDPE or HDPE films can further enhance moisture resistance. For applications requiring stronger oxygen barriers, integrating an EVOH layer into BOPE films delivers reliable performance, making these structures well suited for modern flexible packaging.

If you have any questions or would like further information about our juice pouch packaging solutions, don’t hesitate to get in touch.

Wishing you a wonderful day!