Different types of packing bags greatly enhance our daily convenience, and among them, stand-up pouches are particularly popular due to their unique design and functionality.

Stand-up pouches are commonly used in industries such as food and beverages because they can stand independently on a flat surface, making them easy to store and display. A specific kind of stand-up pouch that many people appreciate for its practicality and ease of use is the juice spout pouch.

So, what materials are used to make juice spout pouches?

Let’s explore the details of this type of stand-up spout pouch.

Packaging Foil Materials

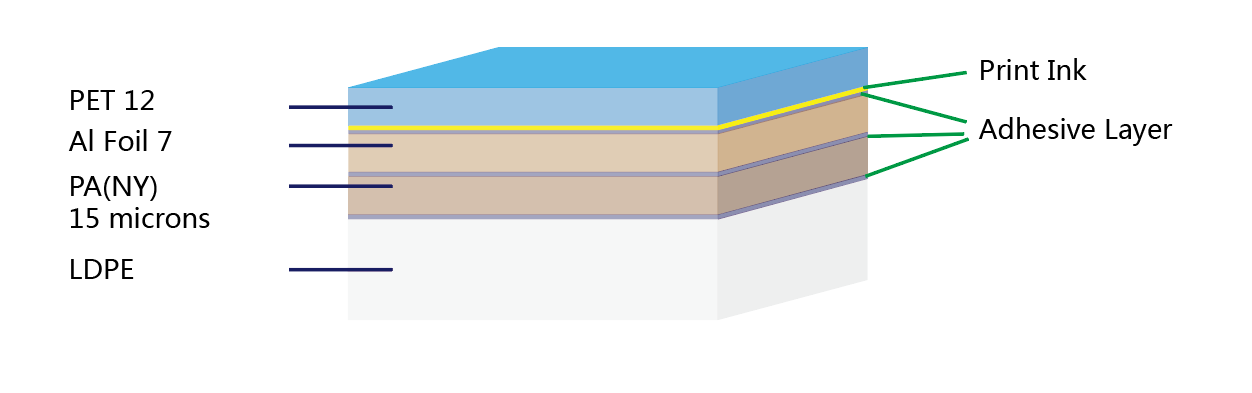

It is made of four layers, with the outside PET film as the print substrate film, the AL and PA film as the middle reinforced layer, and finally, the LDPE film as the inner sealing layer.

Next, let’s get a deeper understanding of each substrate film material.

PET Film

PET film, also known as polyester film, has a wide range of applications in packaging, particularly in bags. It possesses several excellent characteristics.

Firstly, PET film is known for its high toughness and strength, offering good tensile strength that makes it resistant to damage during use. This capability helps protect the contents inside the packaging effectively. Secondly, it boasts high transparency, allowing the items within the packaging to be visible, which enhances the display appeal of the products.

Additionally, PET film exhibits good chemical resistance, enabling it to tolerate most chemical substances while ensuring stability in various environments. Its barrier properties are also noteworthy, providing effective protection against moisture and oxygen, which helps to extend the shelf life of products, especially food items.

In packaging bags, PET film is frequently used as an outer layer or an intermediate layer, often combined with other materials to improve the overall performance of the bags. It is commonly found in food packaging, such as snack bags and beverage bottle labels, and can also be employed in packaging non-food products, including electronics.

The typical thickness of PET film used in the flexible packaging industry is 12 microns (0.48 gauge), so terms like PET12 or 0.48g PET refer to the same thickness. Various types of packaging bags greatly enhance our daily convenience, with stand-up pouches being particularly popular due to their unique design and functionality.

Stand-up pouches are commonly utilized in the food and beverage industry because they can stand independently on a flat surface, making them easy to store and display. One specific type of stand-up pouch that many appreciate for its practicality and ease of use is the juice spout pouch.

Now, let’s explore the materials used to create juice spout pouches and delve into the details of this type of stand-up spout pouch.

Aluminum Film

Aluminum foil is a widely used packaging material that plays a significant role in packaging bags. It possesses several important characteristics.

First, aluminum foil has excellent barrier properties against light, water vapor, and oxygen. This allows it to effectively prevent food from oxidizing, deteriorating, becoming wet, or developing mold, thereby extending the shelf life of various products. Second, due to its high thermal conductivity, aluminum foil can act as an effective medium for transferring heat quickly, making it suitable for applications that require rapid heating or cooling.

Additionally, aluminum foil’s outstanding corrosion resistance makes it ideal for packaging chemical products, as it can withstand the effects of most chemical compounds. It is also highly pliable, allowing it to be shaped and thickened to meet the specific requirements of different types of packaging bags.

In terms of applications, aluminum foil is commonly used in food packaging, particularly for products that require high preservation standards, such as meat, dairy products, coffee, and tea. In pharmaceutical packaging, it helps ensure the stability and effectiveness of medications. Furthermore, in the packaging of electronic products, aluminum foil provides protective qualities, including antistatic and moisture-proof features.

BOPA Film

As a common packaging material, nylon plays an important role in the production of packaging bags. It has many characteristics.

First of all, it has high strength. It has very high strength and toughness and is not easily broken even when loaded with heavy objects or squeezed during transportation, which can provide good protection for items. Secondly, it has good wear resistance. During daily use and handling, packaging bags may rub against various surfaces. The wear resistance of nylon ensures the service life of packaging bags. Thirdly, it has chemical resistance. It has a certain tolerance to many chemical substances and can remain stable in different environments, which is suitable for packaging products of various properties. In addition, nylon has better gas barrier properties. Although it is not as good as some professional barrier materials, it has a certain barrier effect on gases and helps to extend the shelf life of products such as food.

In terms of application fields, nylon is often used in food packaging, such as nuts, dried meat products, and other foods that need certain protection and preservation; in the industrial field, it can be used to package various parts and raw materials to protect products; it is also often used in express packaging because of its high strength and can withstand various pressures during transportation.

LDPE Film

LDPE means low-density polyethylene film, which is the most commonly used inner sealing layer for standing juice bags. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, the LDPE membrane can be modified against the requirements of specific products and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

Great Standup Effect

The customer artwork is printed on the first layer of PET film in the gravure printing system. Four layers are then bonded together to create a finished laminated foil material using either dry or solvent-free lamination.

Typically, we refer to the finished laminate as PET12/AL7/BOPA15/LDPE foil. So, how does this foil structure perform when used for stand-up juice bags? Will it break during transit?

PET film is quite stiff, making it suitable for creating a good stand-up effect for bags. For some low-volume packages under 500ml, a PET12/LDPE foil laminate can also provide sufficient support for most products. When aluminum film and BOPA film layers are incorporated into this foil laminate, the resulting stiffness of the finished foil will effectively maintain a stand-up profile.

You are advised to watch this video of the 800ml apple juice aluminum foil spout doypack.

Mechanical Property

The juice product will be protected by spout packaging throughout the processes of filling, transportation, and distribution. This spout package is designed to withstand extreme conditions and will not shatter in emergencies, such as unexpected delivery shocks or packages falling from shelves.

At our manufacturing plant, the mechanical integrity of our 800ml juice stand-up sachet is our highest priority. Our quality control system implements rigorous measures to ensure that each order meets the expected standards.

In simple terms, conducting a drop test on a filled package is one of the most reliable methods to assess whether it can withstand sudden, sharp impacts without bursting.

Here, we are going to fill 800 ml of water, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The juice product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of juice products. The table below shows the typical value of the WVTR and OTR of this triplex foil laminate, PET12/AL7/PA15/LDPE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

Technical Data Sheet of 80ml Juice stand-up pouch

Here, we attach the specification sheet of this 80ml juice bag based on foil laminate PET12/AL7/PA/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (MPa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this Matte BOPP/Kraft Paper/VMPET/LDPE laminated foil, you may just read it here.

Also, here is the link for the 3L bag-in-box stand-up juice pouch for your reference.

Of course, you are welcome to reach us if you have any questions regarding juice pouches. Nice day.