The spout stand-up bag is one of the most suitable choices for laundry detergent packaging. The spout design makes it easy to take out the laundry detergent multiple times.The bottom support also makes it easy to place the laundry detergent. This type of bag has good sealing and is easy to take out, suitable for products that need to be taken out multiple times

Let’s explore the details of this 3-liter laundry detergent liquid screw-cap pouch in more detail.

Packaging Foil Materials

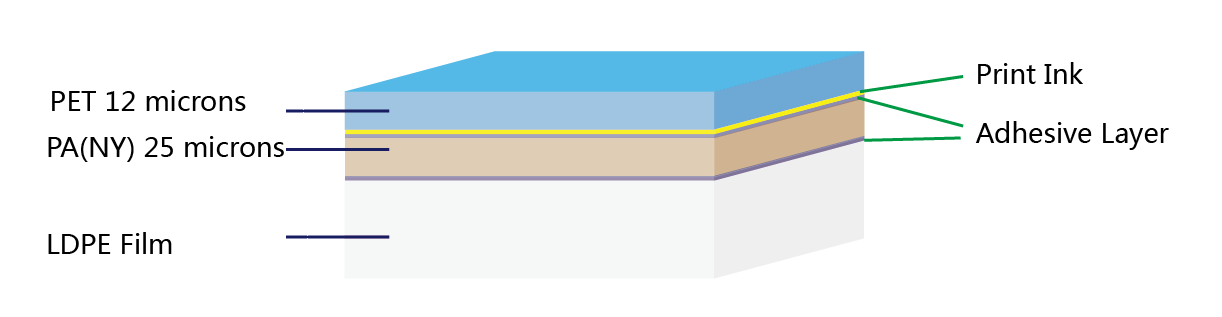

The following figure vividly shows the roll film structure of this 3.5 liter laundry detergent liquid screw cap bag.

This bag is made of three materials: PET, PA, and LDPE. The outer 12-micron PET film serves as the printing substrate, offering excellent mechanical strength and surface clarity. The inner 100-micron LDPE film offers excellent heat-sealing and moisture-proof properties. The PA interlayer provides high strength, effectively protecting the laundry detergent from damage.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET film is one of the most widely used printing substrates in the flexible packaging industry. It offers splendid optical clarity, high gloss, preeminent chemical resistance, stable mechanical strength, impressive dimensional stability, and outstanding printability. ood features allow the customer’s design to be printed accurately and clearly, which can greatly improve the packaging bag’s bearing capacity and quality.

In the flexible packaging industry, the most commonly used thickness for PET film is 12 microns, which is equivalent to 0.48 gauge. Therefore, whenever you see references to PET12 or 0.48 g PET, you can understand that they refer to the same material.

PA Film

PA is also widely used in the packaging field. It has good barrier properties, excellent puncture resistance, and better heat resistance than ordinary plastics. Due to these properties, packaging bags made with PA offer excellent barrier properties against oxygen, odors, and other factors. Furthermore, PA effectively prevents packaging from breaking and is often used in stand-up pouches, often in packaging applications requiring high-temperature sterilization or heat sealing.

LDPE Film

LDPE stands for Low-Density Polyethylene Film. It is the most commonly used inner seal in stand-up pouches. LDPE is lightweight, easy to process, and has good chemical and impact resistance. It is also recyclable, reusable, non-toxic, and durable.

The thickness of LDPE can be adjusted based on product needs. This helps ensure a secure seal and proper protection in different applications.

Mechanical Property

The mechanical properties of PET/PA/LDPE materials are as follows.

The PET layer is notable for its high tensile strength, bending strength, and impact strength, with an impact strength that is 35 times greater than that of other films. It also exhibits excellent resistance to folding. The mechanical properties of PET are relatively stable across different temperatures, and it offers good wear resistance, fatigue resistance, and dimensional stability.

The PA layer is commonly known as nylon film and typically has a thickness of 15 microns (equivalent to 0.6 gauge). This film exhibits excellent mechanical strength, outstanding puncture resistance, and high barrier performance against oxygen. When incorporated into foil laminates, PA15 contributes to a final package that boasts enhanced mechanical strength.

The LDPE layer has a tensile strength of 714 MPa, exhibiting outstanding flexibility and extensibility. However, its mechanical strength, moisture insulation, gas insulation, and solvent resistance are relatively weak.

We prioritize performance in the production of this 3.5-liter laundry detergent liquid screw cap sachet. Our quality control system implements strict measures to ensure that every order meets the expected standards.

In short, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces. You can watch a video similar to this.

Sure, there are reinforced foil structures available for more robust packages for household cleaning liquids as below.

- PA15/PA15/LDPE

- PA15/PA25/LDPE

- PA25/PA25/LDPE

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for Water vapor transmission rate) and OTR (Oxygen Transmission Rate). The table below shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/BOPA/LDPE foil laminate will be able to meet most of the requirements for household laundry detergent liquids. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.85 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.2 |

Technical Data Sheet of 3.5-Liter Laundry Detergent Liquid Doypacks

Here, we attach the specification sheet of this 3.5 liter laundry detergent liquid bag based on foil laminate PET/PA/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Learn more about this foil laminate on our company website.

Now it’s the end. You are welcome to reach us if you have any questions regarding laundry detergent liquid screw cap pouches. Have a nice day!