Sugar, an essential conditment in our daily life, is always occupying a certain place on the conditment shelf. Normally, people would buy a certain amount like 500ml to 1000ml of sugar each time for this family purpose.

Below picture shows a great standup spout pouch for 1000ml sugar granule that serve so well for family package purpose. The pouch is made of triplex transparent film materials which can provide enough stiffness to support an excellent standing profile when the sugar product is filled. It proves itself an appealing bbeauty when it is shown on the goods shelf with the consumers wondering around, quite a catch.

A great package should be able to tell.

Furthermore, the corner spout allows the sugar granules poured out in a well controlled way, which will surely aovid the sharp pop-out of so much volume, and the plastic closure will achieve so fine re-sealing of this package, which create an enclose environment for the sugar products, for a better protection.

The curiosity may arise from the heart of some customers, to have a deeper understanding on the film materials used, and some may start up a plan trying to set their lovely logo on this standup pouch.

As a reliable manufacturer of this standup screw cap bag for more than 10 years in Qingdao, China, well, in this post, we are going to share with you all the details regarding the foil materials of each eye-catching package.

Foil Laminate

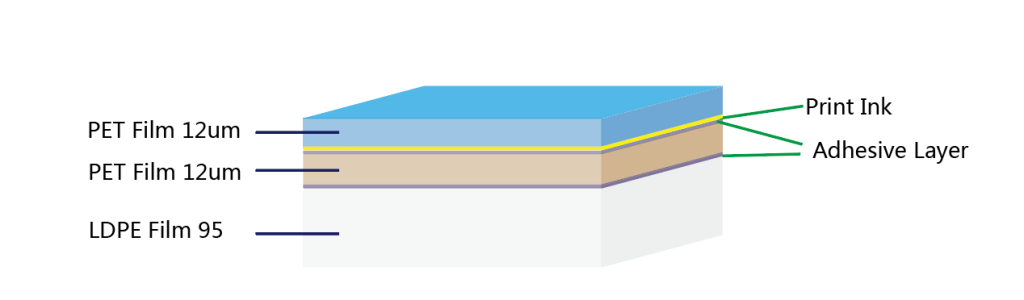

The above graphic shows the details of the triplex foil layers, which consitute the main body of the standup spout pouch.

PET Film 12 microns, is one of the most common used printing substrates in flexible packaging pouches. With great clarity, stable mechanical strength and excellent printability, it is able to present the customer artwork print in great quality.

The middle PET film 12 microns, actually works as the reinforced and supportive layer, which make the foil more robust and stiff.

LDPE film 95 microns, means low density polyethylene film with thickness 95 microns, which is the most used inner sealing layer for the flexible foil laminate. It is able to provide enough sealing strength and airtight property for the final packages.

Thickness

After lamination of these 3 layers which is usually achieved through solvent-free laminate process in our manufacturing plant, the thickness actually will increase in some extent, as of the printing inks and adhesive will of course, take a part of the overall thickness, and the thickness comes at 0.122mm (equals to 122 microns). Please note, as there is still some tolerance with the thickness for the substrate film, especially the thickness of LDPE film fluctuate a lot when it is blown from the extrusion die, so usually we keep a promise to keep the tolerance under +-10% of the expect thickness.

PET Film

PET film, is one of the most common polyester film applied in the flexible packaging and printing area. Now, PET film enjoys a more favorable position in the printing application than nylon film and BOPP film, as it combines several advantages, like great printability, excellent mechanical stabilization in processing, high temperature resistance, durable dyne level in storage.

When PET film works as the outside printed layer, the final foil laminate will be able to stand the high temperature in the heat sealing process, and achieve a smooth sealed surface than BOPP film laminate.

LDPE Film

LDPE, short for low density polyethylene, occupys a large part of the fossil chemical materials in the packaging area. When LDPE film is made into film, the durable property enables it widely applied for the multilayer packages of various products. In this case, anti-static property will be enabled on the film to fight against the sugar dust in the produce and fill operations.

Great Standing Profile of this Foil Pouch

This triplex foil PET12/PET12/LDPE95 is stiff enough to provide a great standing profile for the final products, as you can watch the finished package with 900 gr of sugar granules filled.

Mechanical Strength of this Foil Laminate

Good mechanical strength is required in this foil laminate, as the 1000ml of sugar granules will be well protected, from the product filling, to the distribution process. Not only the film materials are enabled with excellent properties , but also a certain bonding strength should be achieved by the bi-component adhesive. Of course, a series of QC measures are taken in our produce and inspection system.

Here, we are going to share some reliable methods in our plant, to check the mechanical strength of a sealed foil package.

Drop Test

Here, we are going to fill the standup pouch with products, and perform drop test from 16. meter high, separately horizontal and vertical drop. The drop test is considered as the most simanteous way when the package falls off the good shelf.

Observing from the above video, the standup screw cap pouch broke at the second drop from 1.6 meter, and did not break when it is dropped horizontally. That is actually strong enough to protect and distribute the sugar products.

Anti-pressure Test

In this test, we need to get the empty bag inflated, and then well sealed. A certain pressure is applied on top for a certain time to check if it bursts. That is a quite useful way to determine if the sealed bag is strong enough. Just watch the video below for a further understanding.

Video: Anti-Pressue Test

Ok, here we list the details for this triplex foil laminate for this sugar standup pouch, and the tests applied to check the mechcanical strength. Hope it comes into your expect.

Moreover, some customers may still prefer a stronger package, which can be replaced by PET12/PA15/LLDPE foil laminate. It consists a nylon film layer with thickness 15 microns, which is a more robust layer than PET film. Usually, the foil laminate PET12/PA15/LLDPE can be well intended for many liquid products up to 1litre, 2litre, 3lires and even a gallon, such as windshield washer fluis, household laundry liquids, fertilizer liquids etc. So, it can also be a reinforced standup pouch for sugar granules up to 1000ml.

The barrier performance can also be improved with AlOx coated PET film, or SiOx coated PET film if the customer wants to keep the clear transparent window.

Of course, the clarity of this foil laminate can also be improved to a higher level, which may show the sugar granules in a refined way.

We are going to have a further analysis on the performance of improved foil material in future posts. Of course, do not hestitate to reach me whenever you have questions regarding the packages.