Compostable pouch packages are becoming more and more acceptable and affordable for many businesses, as this package will be able to reduce the plastic pollution released by traditional fossil chemicals materials to our human planet. As well known, kraft paper is made of pure fiber plant materials, and in flexible packaging area, it is a natural, biodegradable, and compostable paper material which can be well intended for many products.

To convert the kraft paper into various types of packages, like rollstock, bottom gusseted doypack, quad sealed bag, flat bottom standup pouch, flat bag, side gusset bag etc, a furthe inner liner sealing layer will need to be applied over the surface of kraft paper substrate.

In current market, there are 3 types of liner film materials which can be well intended for compostable pouch, as below

- PLA Film (also called BOPLA film)

- PLA+PBAT Film

- PBS Film

As PBS film is of much higher price which cause a big trouble for its commercial application, so in this post, we will talk about the difference of Kraft paper/PLA and Kraft paper/PLA+PBAT pouch, that are more popular in the market.

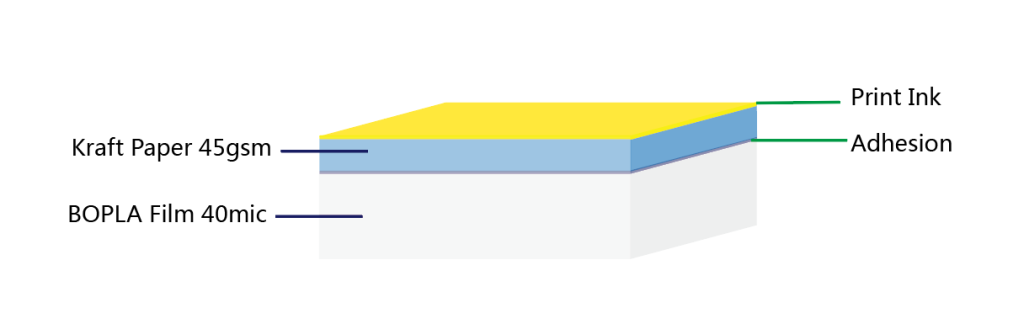

Kraft Paper/BOPLA Foil Pouch

This above picture shows the comostable standup pouch with foil laminate kraft paper 45gsm/BOPLA40micron, with texts printed on the surface of kraft paper. You can check the below graphic for further understanding.

The below vidow shows a further profile for this compostable standing doypack.

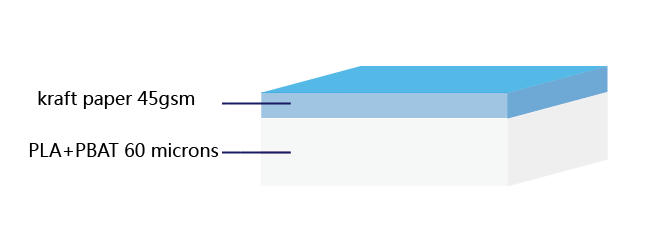

Kraft Paper/PLA+PBAT Foil Pouch

This picture shows the unprinted compostable standup doypack with foil materials kraft paper 45gsm/PLA+PBAT60 microns. It is semi-transparent, with coffee beans filled in, and people can see the blur image of the products.

Check this video below for a further understanding.

Full plant-based film materials

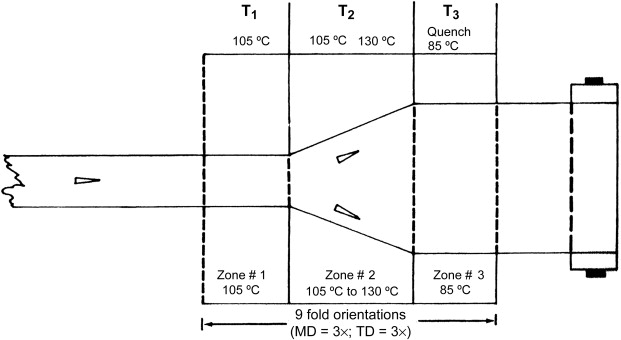

Kraft Paper/BOPLA film can be considered as fully plant-based materials packages, as actually BOPLA (short of biaxial orientated polylactic acide) film is made of pure poly-lactic acide, which is a thermoplastic monomer derived from renewable, organic sources such as usually derived from cassava, corn-startch or sugarcane.

Machine direction orientation (short as MDO) and transverse direction orientation (short as TDO) can be achieved on the orintentation zone of the produce line after the film is cased onto the chilling roller.

Anyway, BOPLA film can be taken as full plant-based film materials.

However, PLA+PBAT film is actually a blown film from the mixes of PLA and PBAT resin. PBAT, short for Polybutylene Adipate Terephthalate, is a new type of biodegradable and compostable plastic which is derived from fossil chemicals. Therefore, the final blown PLA+PBAT film should not be considered as full plant-based film materials.

So Kraft Paper/BOPLA foil pouch can be taken as full plant-based materials pouch, however Kraft Paper/PLA+PBAT foil pouch is not the one.

Stiffness

BOPLA film presents much better mechanical property after orientation, and the stiffness increases so much, and then laminated with kraft paper, the final foil laminate will be much better stiffness than kraft paper/PLA+PBAT foil.

Standup effect

With better stiffness, actually Kraft paper/BOPLA pouch will present better standing effect than Kraft paper/PLA+PBAT pouch. However, in most cases, the standing effect of Kraft paper/PLA+PBAT pouch will be great for most of the products.

Sealing Property

When working as inner sealing layer, BOPLA film is much fragile than PLA+PBAT film. So Kraft paper/BOPLA pouch can only be intended for light-weight products package, like 5~100g. As you can check the pressure test in the below video, when we strikes on the kraft paper/BOPLA pouch, it is much easier to burst.

However, when a person stands on top of Kraft paper45g/PLA+PBAT50 compostable foil pouch for 10~15 seconds, it will not burst. That proves the sealing strength for Kraft paper45g/PLA+PBAT50 compostable foil bag is so great that it can be well intended for the packages for heavy-weight products.

Of course, the performance of these two foil structures will be different in some other items, with items listed as below

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Impact Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ablity (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

You are advised to have a further understanding based on the technical data sheet as below.

TL-21925 Technical Data Sheet of Compostable zipper pouch Kraft45g-BOPLA40

TL-21924 Technical Data Sheet of Compostable zipper pouch Kraft45g-PLA+PBAT50

You may watch the video for a further understanding on the difference of Kraft Paper/BOPLA foil pouch and Kraft paper/PLA+PBAT Foil Bag.

Ok, that’s all what we need to say about these two compostable pouches, and if you need sample bags to test on your own products, please just free to reach us at office@valuepackaging.cn